Unlocking the Advantages of Rubber Lubricant for Enhanced Performance

Table of Contents

- Benefits of Using Rubber Lubricants for Extended Equipment Lifespan

- Key Performance Metrics: How Rubber Lubricants Improve Efficiency

- Statistics on Reduced Friction and Wear Rates with Rubber Lubricants

- The Impact of Rubber Lubricants on Energy Savings in Industrial Applications

- Environmental Considerations: Biodegradable Rubber Lubricants and Their Benefits

- Cost-Effectiveness of Rubber Lubricants in Maintenance Programs

- FAQS

- Conclusion

- Related Posts

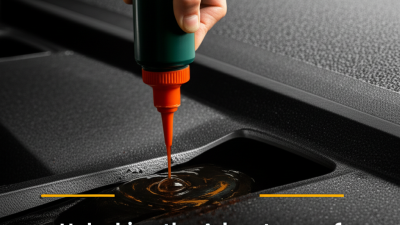

These days, when it comes to manufacturing, everyone’s really chasing that perfect balance of performance and efficiency. Part of that push involves turning to specialized lubricants — like rubber lubricants — which have become pretty vital. I recently came across a report from the Global Lubricants Market Analysis, and it looks like the demand for top-tier lubricants is expected to skyrocket. That makes sense, given how manufacturing methods keep evolving and the growing push for energy-saving solutions. Shanghai Jiongcheng Industrial Co., Ltd. is right there at the forefront of this trend. They’re experts in crafting comprehensive lubrication solutions, especially for high-temperature uses like compressors and vacuum pumps.

Their focus on cutting-edge research, top-notch production tech, and strict quality controls really pays off — their rubber lubricants aren’t just good, they’re built to last, helping machines run longer and cut down on downtime. In this competitive market, leveraging the benefits of rubber lubricants can really make a difference — it’s all about making operations smoother and saving some serious costs for manufacturers.

Benefits of Using Rubber Lubricants for Extended Equipment Lifespan

Rubber lubricants are pretty key when it comes to making equipment last longer, especially in industries that rely on heavy machinery. They do a great job of reducing friction between moving parts, which means things run smoother and wear and tear aren’t as big of an issue. Plus, because rubber can conform to surfaces so well, it creates a tight seal that keeps out dirt, dust, and other contaminants—helping everything stay in good shape for a longer time.

When it comes to mill liners, adding rubber lubricants can really make a difference. These liners go through a lot—stress, chemical exposure, you name it—so using specialized lubricants helps protect them from quick damage and degradation. That basically means less money spent on repairs and downtime, and more reliability throughout the production process. So, honestly, rubber lubricants aren’t just about improving performance—they’re a smart move for keeping things running smoothly in the long run. As industries keep evolving, choosing advanced options like rubber-based lubricants is becoming more and more important if you’re aiming for maximum efficiency and longer-lasting equipment.

Key Performance Metrics: How Rubber Lubricants Improve Efficiency

Rubber lubricants have really become a game-changer across a bunch of different industries. They’re helping improve efficiency and performance in a big way. Basically, by cutting down on friction, these lubricants help machinery and parts last longer. That means less downtime, fewer repairs, and lower maintenance costs overall. What’s cool is that rubber lubricants form a protective layer that not only slows down wear and tear but also handles extreme temperatures and pressures pretty well. So, even in tough conditions, things keep running smoothly.

On top of making equipment last longer, rubber lubricants also boost how efficiently everything runs. Thanks to their special formulation, moving parts glide more easily, which can lead to faster production and better quality. This is especially helpful in manufacturing setups where speed and precision really matter. Plus, because they stick to surfaces so well, rubber lubricants stay in place and keep things lubricated, even in pretty challenging environments. That way, they prevent the buildup of contaminants and make sure things keep working consistently no matter what.

Unlocking the Advantages of Rubber Lubricant for Enhanced Performance

This chart illustrates the key performance metrics showing how rubber lubricants enhance efficiency across various applications.

Statistics on Reduced Friction and Wear Rates with Rubber Lubricants

When it comes to keeping machinery running smoothly, one thing that often gets overlooked is the type of lubricant we use. Believe it or not, switching to rubber-based lubricants can make a pretty big difference. Recent data shows that these lubricants can cut down friction and wear significantly—up to about 30% compared to the regular oils we usually go for. That means machines run more smoothly and use less energy, which is always a plus.

Plus, the wear and tear on parts also drops quite a bit—studies are pointing to around 40% less damage over time. That’s great news because it means your equipment lasts longer, and you’re not constantly fiddling with repairs or replacements. It’s a win-win in terms of saving money.

You see these rubber lubricants popping up everywhere—cars, industrial machines, you name it—and folks are starting to realize how much they can improve overall performance. It’s clear that more places are beginning to adopt them for better efficiency and longevity.

The Impact of Rubber Lubricants on Energy Savings in Industrial Applications

You know, rubber lubricants are really gaining recognition for how much they can help save energy in industrial settings. Basically, by cutting down on friction and reducing wear on machinery, these lubricants can make equipment run more smoothly and efficiently. I came across a recent study that looked at mandatory energy audits across different industries, and it showed that companies using rubber lubricants saw up to a 10% drop in their energy use during operations. That’s a pretty big deal, especially in factories where energy costs make up a large chunk of the expenses.

On top of that, using rubber lubricants seems to help machines last longer and cut down on maintenance costs. The data suggests that companies investing in these lubricants often see their money back through less downtime and fewer repairs. Take the automotive manufacturing industry, for example — they’ve noticed improvements in line efficiency and quality control when they switch to rubber lubricants. As more industries look for greener, more sustainable options, rubber lubricants really stand out as a smart way to keep things running smoothly while being kinder to the environment.

Environmental Considerations: Biodegradable Rubber Lubricants and Their Benefits

You know, biodegradable rubber lubricants are really starting to get some attention these days, especially as more companies become conscious about the environment. The thing is, traditional lubricants can be kinda problematic—they often contain chemicals that can mess up soil and water over time. On the flip side, biodegradable options are designed to break down naturally, so they don’t stick around and cause long-term damage. That’s a big plus, not just because it helps meet regulations, but also because it fits right in with the whole trend towards more sustainable, eco-friendly industrial practices. No wonder more companies are seeing them as a pretty attractive choice.

Plus, don’t think that going green means sacrificing performance. These biodegradable rubber lubricants are actually pretty versatile—they work just as well in lots of different applications. They can help extend the life of equipment, cut down on friction and wear, just like traditional ones. And since they’re made from renewable resources, manufacturers can also lower their carbon footprint without giving up efficiency. Making the switch to biodegradable lubricants isn’t just about being environmentally responsible. It’s really about taking a smart step towards sustainable growth and staying competitive in a world that’s more focused on being green than ever before.

Cost-Effectiveness of Rubber Lubricants in Maintenance Programs

When you're looking into maintenance programs, choosing the right lubricant can really make a difference in both how well things run and how much you end up spending. Rubber lubricants, in particular, tend to stand out as a pretty handy option because of their unique benefits. Unlike the usual lubricants, these rubber-based ones are great at resisting wear and playing nicely with different materials. Basically, using rubber lubricants can help extend the life of machinery parts, which means fewer repairs and replacements over time—saving you money in the long run.

Plus, they’re often more eco-friendly than petroleum-based lubricants. Since they’re biodegradable and non-toxic, they’re a better fit for settings where environmental impact really matters. Integrating rubber lubricants into your maintenance routine not only boosts how smoothly your equipment runs, but also shows you’re serious about sustainability. It’s a win-win: better performance and a more responsible approach to industrial upkeep, which can really add up to a healthier bottom line and a bit less guilt about environmental impact.

FAQS

: Rubber lubricants can significantly reduce friction rates by up to 30% and decrease wear rates by up to 40%, leading to smoother operation, less energy consumption, and extended machinery lifespan.

Rubber lubricants offer better performance by reducing both friction and wear rates more effectively than conventional lubricants, resulting in improved operational efficiency.

Rubber lubricants can be effectively used in various applications, from automotive to industrial machinery, improving performance across multiple sectors.

Biodegradable rubber lubricants are being recognized for their ability to break down naturally, which minimizes long-term environmental impact and aligns with the growing demand for sustainable industrial practices.

Biodegradable rubber lubricants maintain efficiency and can enhance equipment longevity while reducing friction and wear similarly to traditional lubricants.

They help reduce soil and water contamination risks associated with traditional lubricants, and their use supports regulatory compliance and eco-friendly industrial solutions.

Yes, reduced wear and longer equipment lifespan with rubber lubricants minimize maintenance and replacement frequency, leading to significant cost savings.

Biodegradable rubber lubricants are often made from renewable resources, helping manufacturers reduce their carbon footprint while maintaining performance.

Companies can operate more sustainably, satisfy environmental regulations, and appeal to eco-conscious consumers by choosing biodegradable rubber lubricants.

Yes, biodegradable lubricants often meet and exceed regulatory requirements, making them a compliant choice for industries focused on environmental responsibility.

Conclusion

Rubber lubricants really pack a punch when it comes to boosting the performance and lifespan of all kinds of industrial equipment. They do a great job of cutting down friction and wear, which means your machinery lasts longer and runs more smoothly. And honestly, that extra efficiency? It’s a big deal—time and again, it proves to be a key factor in overall performance. Plus, there’s solid data showing that these lubricants help save energy, which translates to some pretty nice savings on maintenance costs. On top of that, biodegradable rubber lubricants are a win for the environment, helping industries stay eco-friendly while keeping things running efficiently.

Here at Shanghai Jiongcheng Industrial Co., Ltd., we use cutting-edge technology and carefully formulated chemicals to get the best out of our lubricants. That includes products made to handle high temperatures. We’re all about providing complete lubrication solutions, focusing on rubber lubricants that keep compressors, vacuum pumps, and refrigeration units working perfectly across different industrial settings.

Related Posts

-

Discover Outstanding Products from China with the Best Reliant Dust Collector 720 for Global Buyers

-

7 Compelling Reasons to Choose the Right Cyclone Dust Collector for Your Business

-

Advantages of Using the Best Reliant Dust Collector 720 for Your Manufacturing Needs

-

Top Strategies for Selecting the Best Reliant Dust Collector A Guide for Global Buyers

-

7 Best Craftex Dust Collector Reviews for Efficient Industrial Use

-

What is the Ultimate Guide to the Best Environmental Protection Solutions