How to Choose the Right Ingersoll Rand Lubricant for Your Equipment Needs

Table of Contents

- Factors to Consider When Selecting Ingersoll Rand Lubricants

- Understanding Different Types of Ingersoll Rand Lubricants Available

- Evaluating Compatibility with Your Specific Equipment Needs

- Determining the Optimal Lubrication Frequency for Your Machinery

- Guidelines for Proper Application and Maintenance of Lubricants

- Common Mistakes to Avoid When Choosing Lubricants for Equipment

- FAQS

- Conclusion

- Related Posts

When you're thinking about keeping your equipment running smoothly and lasting longer, picking the right lubricant is a big deal. Ingersoll Rand Lubricants offers a wide variety of products designed to suit different operational needs—whether it’s for industrial or commercial use, they've got reliable solutions. At Shanghai Jiongcheng Industrial Co., Ltd., we focus on all-in-one lubrication solutions, including high-temperature chain lubricants, compressor oils, vacuum pump lubricants, and refrigerant compressor lubricants. We’re really committed to using the latest tech in research and production, so our lubricants meet top-notch quality standards. By combining our expertise with the trusted reliability of Ingersoll Rand Lubricants, we help our customers make smarter choices—ones that boost their equipment’s efficiency and lifespan, ultimately helping them succeed in their operations.

Factors to Consider When Selecting Ingersoll Rand Lubricants

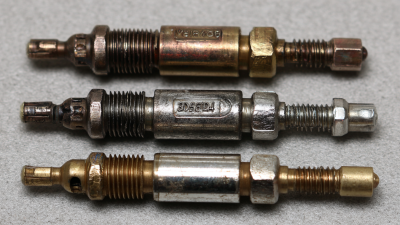

When you're trying to pick the right Ingersoll Rand lubricant for your equipment, there are a few key things you wanna keep in mind to make sure everything runs smoothly and lasts longer. First off, you really need to know exactly what kind of machinery you're dealing with because different machines have their own lubrication needs. For example, rotary compressors often need synthetic oils that can handle really high temperatures and pressures, while reciprocating compressors might do better with special oils that help prevent wear and corrosion.

When you're trying to pick the right Ingersoll Rand lubricant for your equipment, there are a few key things you wanna keep in mind to make sure everything runs smoothly and lasts longer. First off, you really need to know exactly what kind of machinery you're dealing with because different machines have their own lubrication needs. For example, rotary compressors often need synthetic oils that can handle really high temperatures and pressures, while reciprocating compressors might do better with special oils that help prevent wear and corrosion.

Another thing to think about is the environment where your equipment is operating. If it's in a high-stress or high-temperature setting, you'll want a lubricant that's super stable and resistant to breaking down. Don’t forget to check out what the manufacturer recommends—pay attention to the oil viscosity and any recommended additives. This will help you pick something that’s actually suited for your equipment. And, of course, it’s a good idea to make sure the new lubricant will play nicely with what’s already there—mixing incompatible oils can lead to foaming or sediment buildup, which nobody wants because it can really mess with performance.

All in all, a little research and paying attention to specifics can save you a lot of headaches down the line.

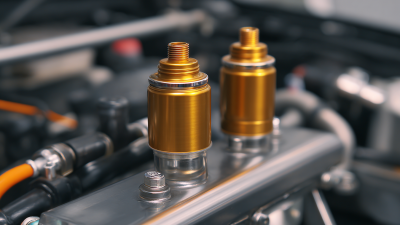

Understanding Different Types of Ingersoll Rand Lubricants Available

When you're choosing the right lubricant from Ingersoll Rand for your equipment, it’s really important to get a good handle on the different types out there and what they specifically offer. Ingersoll Rand has a range of lubricants designed for all sorts of applications — from oils for air compressors, to synthetic greases, and even specialty lubricants built for tough, extreme conditions. Did you know? According to the Lubrication Engineers’ 2020 report, picking the correct lubricant can boost your equipment’s efficiency by up to 20%. Not only that, it helps keep your machinery running longer and performing at its best.

Different lubricants work better in different environments. For example, synthetic lubricants are fantastic at resisting breakdown when things heat up and protecting against wear — perfect for those demanding, high-temperature jobs. For more everyday use, Ingersoll Rand usually recommends ISO-grade oils, which are pretty much the industry standard for efficiency and protection. The thing is, choosing the wrong lubricant can actually end up costing you a lot more money in the long run. A study by the National Lubricating Grease Institute found that poor lubrication can bump up maintenance costs by as much as 30%.

Evaluating Compatibility with Your Specific Equipment Needs

When you're trying to pick the right Ingersoll Rand lubricant for your gear, one thing you definitely want to keep in mind is making sure it’s compatible with your specific equipment. Whether you’re dealing with pneumatic tools, compressors, or bigger industrial machinery, each one needs a lubricant specially designed to handle its unique needs. I read somewhere that, according to the Machinery Lubrication Institute, using the right type of lubricant can actually boost your machine's lifespan by about 30% and cut down maintenance costs by around 20%. Pretty impressive, right? It really shows how important it is to match the lubricant’s properties to your equipment’s working environment — that’s the best way to keep everything running smoothly and efficiently.

Of course, making sure it’s compatible also means understanding what materials you’re dealing with and what conditions they’ll be exposed to. For example, Ingersoll Rand has a range of synthetic and mineral-based lubricants — some are perfect for high-temperature stuff, while others are better if your equipment might see moisture, dust, or rough conditions. The National Lubricating Grease Institute points out that using the wrong lubricant can actually cause equipment to fail — buildup, wear, you name it. So, a good rule of thumb? Always check your equipment manuals and stick to what the manufacturer recommends. That way, you’re not just picking a lubricant that matches viscosity and temp specs, but also one that helps keep your machinery reliable and running longer.

Lubricant Compatibility Evaluation for Equipment Needs

This chart represents the compatibility rating of various lubricant types based on their performance with different equipment categories.

Determining the Optimal Lubrication Frequency for Your Machinery

Picking the right lubricant for your equipment really makes a difference when it comes to keeping things running smoothly and making your machinery last longer. One thing you can't overlook is how often you should be lubricating your machines—that’s key to making sure everything stays in top shape. If you keep an eye on how your equipment is operating—stuff like temperature and load—you can come up with a personalized lubrication schedule that works best for your setup and keeps things running efficiently.

A good rule of thumb is to check the operating conditions regularly. For instance, if your machinery is running hot or dealing with heavy loads, you might need to lube up more often. Also, don’t forget to follow the manufacturer’s advice and think about your specific environment. Say you’re working in really high-temperature setups—that’s when specialized lubricants, like high-temp chain oils, come into play and help prevent early wear and tear.

At Shanghai Jiongcheng Industrial Co., Ltd., we’re passionate about offering lubrication solutions that are just right for different industrial needs. Thanks to our cutting-edge tech and research, we develop lubricants for compressors, vacuum pumps, and refrigerated systems that really deliver peak performance. By choosing from our range of high-quality lubricants, you’ll boost your machinery’s reliability and cut down on those unexpected breakdowns or downtime—that's what we’re here for.

Guidelines for Proper Application and Maintenance of Lubricants

When you're picking out the right Ingersoll Rand lubricant for your equipment, it's super important to understand how to apply and maintain it properly. I read somewhere—actually, a report from the National Lubricating Grease Institute—that over half of equipment breakdowns come down to bad lubrication habits. That really shows just how much of a difference it makes not only choosing the right lubricant but also using it correctly to help your machines last longer.

To get the best performance, make sure you stick to the application schedules and amounts that the manufacturer recommends. For example, Ingersoll Rand points out that using the right amount of lubricant can cut down on friction and wear—that’s a big deal because those two issues can cause up to 20% of energy loss in your equipment. It’s also a good idea to keep an eye on the lubricant itself—check for dirt, contamination, or signs it’s breaking down. Setting up a regular maintenance routine can really pay off by keeping things running smoothly and avoiding those costly downtimes. Basically, following these best practices really helps keep your machinery in top shape.

Common Mistakes to Avoid When Choosing Lubricants for Equipment

When you're choosing lubricants for your equipment, it's surprisingly easy to overlook some pretty crucial factors. This can often lead to equipment not performing as well as it should or, worse, racking up higher maintenance costs than you'd like. A common mistake I see is folks not really considering the specific conditions their machines are operating under—things like temperature, load, or speed. A 2021 industry report by the International Lubricants Association pointed out that choosing the wrong lubricant can actually cut your equipment’s efficiency by up to 20%. That’s a big deal! It just goes to show how important it is to match your lubricant specs carefully to what your machinery needs.

Another mistake that gets made pretty often is not double-checking whether the lubricant you're using is compatible with the materials and additives in your equipment. Using something that's not quite right can cause chemical breakdowns and speed up wear and tear on your parts. Companies like Shanghai Jiongcheng Industrial Co., Ltd. stress how vital thorough research and quality checks are when developing lubricants. They've got tons of experience, especially with compressor and vacuum pump lubricants, ensuring their products are built to perform well even in tough conditions—like high temperatures—thanks to tested chemical formulations. Paying attention to these details can really make a difference, helping your equipment last longer and run more smoothly.

FAQS

: Choosing the correct lubricant can lead to a 30% increase in machine life and a 20% reduction in maintenance costs, which enhances performance and efficiency.

It's crucial to consult equipment manuals and manufacturer recommendations to ensure the lubricant meets viscosity and temperature requirements and is suitable for the specific operational environment.

Ingersoll Rand offers a range of synthetic and mineral-based lubricants designed for various applications, including those facing high temperatures or exposure to moisture and dust.

Utilizing the wrong lubricant can lead to equipment failure due to buildup or inadequate protection against wear, significantly impacting machinery performance.

Assessing your machinery's operating conditions, such as temperature and load, and following manufacturer recommendations can help establish a tailored lubrication schedule.

Higher operating temperatures and heavier loads typically require more frequent lubrication to ensure effective protection and performance.

Shanghai Jiongcheng Industrial Co., Ltd. specializes in providing integral lubrication solutions, including compressor lubricants, vacuum pump lubricants, and refrigerated compressor lubricants.

Utilizing high-quality lubricants can enhance the reliability of machinery and minimize unexpected downtime, ultimately improving operational efficiency.

It's essential to consider the specific requirements of your machinery, including operational demands, environmental conditions, and recommendations from the equipment manufacturer.

Yes, specialized lubricants, such as high-temperature chain lubricants, are available for equipment used in high-temperature settings to prevent premature wear.

Conclusion

Picking the right Ingersoll Rand lubricant for your equipment really matters if you want it to run smoothly and last longer. You’ve got to think about things like what type of lubricant your machinery needs — whether it’s for compressors, high-temp chains, or something else. Making sure that the lubricant is compatible with your equipment is crucial; otherwise, you might run into problems. Also, figuring out how often you should apply it is key to keeping things running efficiently without overdoing it.

And don’t forget, following some basic tips on how to properly maintain and use these lubricants can help you avoid common mistakes that might lead to equipment breakdowns. Here at Shanghai Jiongcheng Industrial Co., Ltd., we use the latest technology and strict quality checks to offer a complete lubrication solution that’s customized for your needs. Our goal is to keep your machines running smoothly and effectively with the right Ingersoll Rand lubricant in hand.

Related Posts

-

Top Strategies for Choosing the Best Lubricant Oil Can for Your Business Needs

-

5 Hidden Benefits of Using Synthetic Lubricant Spray You Never Knew About

-

7 Best Benefits of Using Non Detergent Lubricating Oil for Your Machinery

-

What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

-

How to Select the Right Thread Lubricant for Your Specific Needs

-

Understanding the Benefits of Purified Mineral Oil in Modern Applications

Blog Tags: