How to Choose the Right Dust Collector Replacement Filters?

Table of Contents

- Understanding the Importance of Dust Collector Replacement Filters

- Identifying Different Types of Dust Collector Filters Available

- Evaluating Filter Efficiency and Performance Ratings

- Considering the Size and Compatibility of Replacement Filters

- Assessing Material and Construction Quality of Filters

- Analyzing Cost-Effectiveness and Longevity of Filter Options

- Consulting Manufacturer Recommendations and Specifications

- Essential Guide to Choosing the Right Cartridge Filter for Your Dust Collector: Key Features and Considerations

- FAQS

- Conclusion

- Related Posts

Picking the right replacement filters for your dust collector isn't just a small detail – it’s actually pretty crucial to keeping the air clean in industrial environments. I mean, according to a 2022 report from the EPA, bad air quality can really put workers’ health at risk. Breathing in those tiny particles? Yeah, it can cause serious respiratory problems. So, choosing the right filters isn’t just about ticking boxes – it’s about actively reducing those health hazards.

And get this, the market for dust collection systems is expected to grow pretty steadily, with a compound annual growth rate of about 4.1% from now through 2028. That just emphasizes how important it is for folks to really understand their filter options. Still, a lot of companies struggle with picking the right filters — they often overlook stuff like what material the filters are made of, how efficient they are, or whether they actually work with their existing systems.

It’s not just about following regulations; it’s about making sure the workspace is safe. Sometimes, companies skip over the specific needs of their equipment, which can lead to wasted effort and inefficiencies. Plus, keeping tabs on how long filters last is usually underestimated. Not paying enough attention to this can end up costing more in the long run — more frequent replacements and higher operational costs. At the end of the day, taking the time to choose and maintain your dust collector filters properly really pays off in keeping things running smoothly and safely.

Understanding the Importance of Dust Collector Replacement Filters

When selecting dust collector replacement filters, understanding their importance is crucial. Dust collectors serve a vital role in maintaining air quality. They help remove harmful particles from the environment. Without effective filters, these pollutants can circulate back into the air. This leads to health problems for workers and potential damage to equipment.

Tips: Regularly check the condition of your filters. A filter that appears dirty may still be functional. Don't assume all filters need to be replaced at the same time. Observe their performance closely.

Selecting the right filter can optimize dust collection efficiency. Different applications require different filter types. Some tasks generate fine dust, while others create larger particles. Knowing the specific needs of your operation will help in making the right choice. Also, consider factors like airflow and filter material. It's not always clear what works best, so be prepared to experiment.

Tips: Document filter performance over time. This helps in understanding what filter works best for your setup. It can be enlightening to see why specific filters are more effective. Each choice can make a difference in overall efficiency and safety.

Identifying Different Types of Dust Collector Filters Available

Choosing the right dust collector replacement filters is crucial for maintaining efficient air quality in industrial settings. There are several types of dust collector filters available, each designed to tackle different types of particulate matter. Understanding these types helps in making an informed choice. For example, cartridge filters are commonly used for fine dust, while bag filters work well for larger particles.

With reports indicating that 85% of dust control issues arise from improper filtration, it’s vital to select the correct filter type. Microfiber filters are effective in capturing very fine particles. They can enhance filtration efficiency by up to 95%, according to industry studies. However, these filters may require more frequent replacement and maintenance.

**Tip:** Always evaluate the environment in which your collector operates. Is there a high moisture level? If so, consider filters designed for wet applications. On the other hand, if your operations generate aggressive chemicals, specialized filters might be necessary.

When choosing filters, consider lifecycle costs as well. Higher upfront costs may lead to savings over time through reduced energy consumption and longer lifespan. While it’s tempting to opt for the cheapest option, this could lead to frequent downtime and inefficiency. Research the specific needs of your facility for the best results.

Evaluating Filter Efficiency and Performance Ratings

When choosing dust collector replacement filters, evaluating filter efficiency and performance ratings is crucial. Filters are rated based on their ability to capture particles of different sizes. According to industry reports, a filter with a MERV rating of 13 can capture over 90% of airborne particles that are 0.3 microns in size. However, many filters offer ratings that can be misleading. It's essential to cross-reference these ratings with real-world performance data.

Tips: Check for independent testing results. Look for filters tested under standard conditions. A reliable filter will perform well under various operating conditions.

Additionally, consider the airflow rate. Some filters may restrict airflow more than others. This can lead to decreased efficiency and increased energy costs. Striking a balance between filtration efficiency and airflow is vital. Filters that are too restrictive can cause equipment stress.

Tips: Regularly monitor filter conditions. Replace filters when you notice a drop in performance. This will ensure optimal dust collection efficiency. Remember, not all filters are created equal. Each application may require a different type of filter for best results.

Considering the Size and Compatibility of Replacement Filters

When selecting replacement filters for dust collectors, size and compatibility are crucial. Filters must match the specifications of your dust collector. Measure the dimensions of the existing filter. This includes height, diameter, and connection type. A filter too large or small can lead to inefficient air filtration. Sometimes, people purchase filters based solely on appearance, which can create compatibility issues.

Compatibility also involves material and design. Some filters utilize pleated designs for increased surface area. Others may be flat or cylindrical. Look for filters that maintain the required airflow while maximizing dust capture. If you choose the wrong type, your dust collector may not perform well. Filters crafted from different materials can have varying lifespans, so consider this when making selections.

It's important to verify that any replacement filter fits properly. A loose fit can allow unfiltered air to escape. This may not be evident initially. Regular maintenance checks can help identify fit issues. Take time to research specifications provided by manufacturers. Matching the right filter ensures effective operation and enhances your dust collector's lifespan. Remember, attention to detail in size and compatibility is key.

Assessing Material and Construction Quality of Filters

Choosing the right dust collector replacement filters involves a careful assessment of material and construction quality. Filters play a crucial role in maintaining air quality and operational efficiency in various industries. Common filter materials include polyester, fiberglass, and cellulose. Each material has unique properties affecting its filtration efficiency and durability.

According to a report by the American Filtration and Separations Society, dust collection systems with high-quality filters can reduce airborne particulate matter by up to 99%. However, not all filters deliver this level of performance. For instance, poorly constructed filters may develop tears or leaks, undermining their effectiveness. Regular inspections are vital. Check for any changes in pressure drop, as this can indicate a filter is becoming less effective.

Quality also extends to filter construction. Features like pleating and sealing can impact a filter's lifespan and efficiency. A pleated design increases surface area, leading to better filtration. Reports suggest that filters with proper sealing can last 20% longer than those without. However, it’s essential to re-evaluate these choices periodically, as wear and tear can change performance. The right filter must balance cost and quality to be an effective part of your dust control system.

Analyzing Cost-Effectiveness and Longevity of Filter Options

Choosing the right dust collector replacement filters involves analyzing cost-effectiveness and longevity. Not all filters offer the same value over time. Data from industry reports suggest that HEPA filters last longer, but they come at a higher upfront cost. Traditional pleated filters may be cheaper but could require more frequent replacement.

Longevity is crucial. Studies indicate that high-quality filters can last up to three times longer than budget options. Consider also the impact on operational downtime. Frequent replacements mean lost productivity. A filter's efficiency can degrade after only a few months, which can lead to increased energy costs.

In terms of cost-effectiveness, evaluate total ownership costs. A cheaper filter might seem appealing. However, when factor in replacement frequency and energy usage, the overall costs may skyrocket. Sometimes, investing in a more expensive filter pays off in the long run. Reflections on past choices reveal that opting for lower-priced filters often led to unexpected expenses.

Consulting Manufacturer Recommendations and Specifications

Choosing the right dust collector replacement filters involves careful consideration. Consulting manufacturer recommendations is crucial. Different dust collector brands provide specific guidelines based on their designs and configurations. This ensures compatibility and optimal performance. Manufacturers often highlight the filtration efficiency required for various materials. Follow these specifications closely.

Tip: Always check the filter's material type. This greatly impacts air quality and equipment longevity. A filter that meets manufacturer standards prevents unnecessary wear on machinery.

It’s essential to assess your operational needs too. What type of dust is being collected? Some filters are better suited for fine particles, while others handle larger debris. Consult the specifications regarding particle size and collection efficiency. Using the wrong type of filter can lead to increased downtime and inefficiencies.

Tip: Regularly review filter conditions. Look for signs of wear and tear. A filter that looks fine may not function properly. Trusting recommendations helps, but continuous monitoring is key to maintaining optimal performance. Be proactive rather than reactive. Filters are vital to workplace safety and Environment.

Essential Guide to Choosing the Right Cartridge Filter for Your Dust Collector: Key Features and Considerations

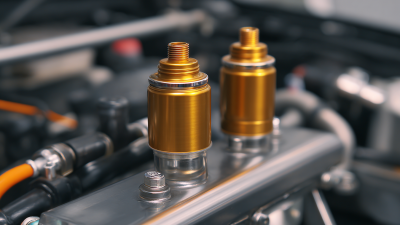

Choosing the right cartridge filter for your dust collector is crucial to achieving optimal performance and efficient air quality management. One of the key features to consider is the filtration area, which is significantly enhanced by unique designs such as the concave fold pattern. This innovative structure ensures that the entire surface of the filter is utilized, allowing for maximum operating efficiency. With this design, dust and particulates are effectively captured, leading to cleaner air and a healthier working environment.

Durability is another essential aspect when selecting a cartridge filter. Utilizing advanced technology in adhesive preparation for bonding ensures that the filter can withstand various operational stresses while maintaining its integrity. The optimal fold spacing of the filter not only promotes uniform filtration across the entire area but also helps to reduce pressure differences within the filter element. This stability improves airflow within systems such as spray rooms and powder rooms, making maintenance and cleaning more manageable.

Additionally, the design features a curved transition at the folding top, which further increases the effective filtration area, thus maximizing efficiency and extending the service life of the filter. The incorporation of a single ring sealing ring with rich elasticity and low hardness contributes to a reliable seal, minimizing the risk of leakage and ensuring effective filtration performance. Selecting a cartridge filter with these considerations in mind will significantly impact the overall efficiency and longevity of your dust collection system.

FAQS

: The service aims to provide users with useful information quickly.

Anyone can use the service. It’s open to all.

Simply access the platform and follow the instructions provided.

There are no specific age restrictions. However, parental guidance is advised for minors.

The information covers various topics, including tips and general knowledge.

Accuracy may vary. Always cross-check with reliable sources.

Yes, user contributions are welcomed. Share your insights and knowledge.

Use the reporting feature on the platform to flag issues directly.

There may be daily limits on usage to ensure fair access for everyone.

Reach out to support for assistance with any technical problems.

Conclusion

When selecting Dust Collector Replacement Filters, it’s essential to understand their significance in maintaining air quality and ensuring optimal operation of dust collection systems. Different types of filters are available, and evaluating their efficiency and performance ratings is crucial to ensure they meet specific operational requirements.

In addition, considering the size and compatibility of the replacement filters will help in achieving a proper fit, while assessing the material and construction quality can enhance durability and filtration effectiveness. Cost-effectiveness and longevity of filter options should also be analyzed to make a sound investment. Finally, consulting manufacturer recommendations and specifications will provide valuable guidance in selecting the right filters for your dust collection needs.

Related Posts

-

What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

-

2026 Best Mineral Lubricant Options for Your Needs?

-

Why Industrial Dust Extractors Are Essential for a Safe Work Environment?

-

Discover Outstanding Products from China with the Best Reliant Dust Collector 720 for Global Buyers

-

Choosing the Right Manufacturer for Best Micro Air Dust Collectors and Key Features to Compare

-

Advantages of Using the Best Reliant Dust Collector 720 for Your Manufacturing Needs

Blog Tags: