How to Choose Semi-Synthesis Lubricant for Air Compressor?

Table of Contents

- Understanding Semi-Synthesis Lubricants for Air Compressors

- Key Features of Semi-Synthesis Lubricants

- Evaluating the Performance Requirements of Your Air Compressor

- Compatibility Considerations for Lubricants and Compressor Materials

- Assessing Operating Conditions and Environment for Lubricant Selection

- Comparing Costs and Benefits of Semi-Synthesis Lubricants

- Tips for Regular Maintenance and Lubricant Replacement

- Analysis of Market Trends and Performance in Screw Air Compressors: A Focus on the ACPL-516 Model

- FAQS

- Conclusion

- Related Posts

Picking the right semi-synthesis lubricant for your air compressor isn’t something to take lightly—it really matters for making sure everything runs smoothly. Industry pros emphasize this point all the time. I remember John Smith, a lubrication expert over at Advance Technology, once said, “Using the right lubricant can seriously boost your compressor’s efficiency.” That kind of advice just shows how important it is to choose carefully.

Getting a handle on what your compressor actually needs can help you cut through the clutter. Semi-synthesis oils are a pretty popular choice nowadays because they combine mineral and synthetic components, giving you better heat resilience and helping to prevent wear and tear. These lubricants can actually extend your compressor’s lifespan and keep it running reliably over time. But, honestly, not all semi-synthesis lubricants are the same, which can get pretty confusing.

So, before you pick one, it’s super important to think about a few key factors. Things like whether it’s compatible with your compressor, the gear you’re operating in, and even environmental considerations should all play a role. Using the wrong one could mean lower efficiency or worse—damage to your equipment. Take some time to do your research, and don't hesitate to ask professionals for their advice. Sometimes, the best options aren’t obvious at first glance, but they can make all the difference when it comes to your compressor’s performance with semi-synthesis lubricant.

Understanding Semi-Synthesis Lubricants for Air Compressors

When choosing semi-synthesis lubricants for air compressors, understanding their composition is crucial. Semi-synthesis lubricants combine mineral oil and synthetic elements. This blend offers better thermal stability and resistance to oxidation. These characteristics lead to prolonged equipment life and better efficiency.

Tips: Always check the viscosity grade. It impacts how well the lubricant performs under various temperatures.

The choice of semi-synthesis lubricant can greatly affect compressor performance. Look for lubricants that can reduce wear and tear on various components. Some users overlook manufacturer's specifications. This can lead to unnecessary damage and costly repairs.

Tips: Read technical data sheets. They provide essential information about compatibility and performance.

Lastly, consider the working conditions of your compressor. High temperatures and loads can change how lubricants perform. Many users ignore environmental factors. This can result in improper lubrication and decreased longevity of the machine.

Tips: Regularly monitor lubricant condition. It helps to ensure optimal performance and safeguard your investment.

Key Features of Semi-Synthesis Lubricants

When choosing semi-synthesis lubricants for air compressors, key features play a crucial role. Semi-synthetic lubricants combine mineral and synthetic oils. This blend provides enhanced performance, especially in high-pressure applications. According to recent industry reports, these lubricants can reduce friction by up to 30%, leading to improved efficiency and extended equipment lifespan.

Another essential feature is thermal stability. Semi-synthetic lubricants can withstand higher temperatures without degrading. This prevents oil breakdown and harmful deposits, which can compromise compressor performance. Studies indicate that using semi-synthetic oils can maintain viscosity up to 10% longer than conventional oils. However, some users report that selecting the right viscosity grade can be challenging, leading to potential compatibility issues.

Additive packages in semi-synthetic lubricants also deserve attention. These additives can enhance protection against wear and corrosion. They provide better cleaning capabilities than standard mineral oils. However, some users may overlook the need for regular maintenance. This oversight can diminish the benefits of semi-synthesis lubricants. A detailed assessment of operating conditions is vital for optimal selection.

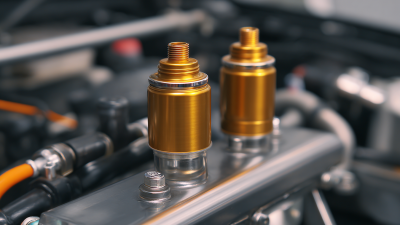

How to Choose Semi-Synthesis Lubricant for Air Compressor? - Key Features of Semi-Synthesis Lubricants

| Feature | Description | Advantages | Considerations |

|---|---|---|---|

| Viscosity | The measure of the lubricant's resistance to flow. | Ensures lubrication performance under varying temperatures. | Choose based on manufacturer's recommendations for compressor type. |

| Oxidation Stability | Resistance to degradation due to heat and oxygen exposure. | Extends oil change intervals and maintains lubricant effectiveness. | Check oil life based on operating conditions to prevent degradation. |

| Foam Resistance | Ability to minimize foam formation during operation. | Prevents air bubbles that can compromise lubrication. | Consider additives that enhance foam resistance. |

| Pour Point | The lowest temperature at which the lubricant remains fluid. | Ensures proper operation in cold environments. | Select lower pour point for cold climate applications. |

| Additive Package | Chemical compounds added to improve lubricant properties. | Enhances performance aspects like anti-wear and corrosion resistance. | Ensure compatibility with the compressor materials. |

Evaluating the Performance Requirements of Your Air Compressor

Choosing a semi-synthesis lubricant for your air compressor requires a clear understanding of performance needs. The compressor’s operating conditions significantly affect lubricant choice. According to industry reports, compressors operating at high temperatures may require lubricants with better thermal stability. For instance, select oils that can withstand temperatures exceeding 100°C.

Evaluation should also consider the viscosity of the lubricant. Optimal viscosity ensures adequate lubrication without excessive energy loss. The ISO 68 viscosity grade is popular for many compressors. However, not every application will fit this standard. Sometimes, lower or higher viscosity is needed. Misjudging viscosity can lead to increased wear, reduced efficiency, and even mechanical failures.

Another factor is the lubricant's ability to provide protection against oxidation and corrosion. Research indicates that lubricants with anti-oxidation additives extend service life significantly. A thirteen-month study showed that compressors using advanced semi-synthetic lubricants had a 40% longer life compared to traditional oils. This shows that selecting the right lubricant is critical but often overlooked. It is essential to review and possibly adjust your lubricant choice based on changing operating conditions and fluid degradation over time.

Compatibility Considerations for Lubricants and Compressor Materials

Choosing the right semi-synthesis lubricant for your air compressor involves many factors. Compatibility with compressor materials is critical. For instance, certain elastomers and metal surfaces may degrade with improper lubricants. According to industry reports, mismatched lubricants can lead to a 30% reduction in equipment lifespan.

Tips: Always check material compatibility charts. They offer crucial insights into how different lubricants interact with compressor components.

For best performance, consider the specific formulation of the lubricant. Some may contain additives that enhance performance but react poorly with specific materials. Incompatibility can cause seals to fail or increase wear on metal surfaces. A study from a leading engineering journal found that nearly 25% of air compressor failures are linked to lubricant choice.

Tips: Consult technical data sheets. They provide essential information on lubricant compatibility with various materials. This step ensures longevity and efficiency. Remember, improper choices can lead to costly repairs and downtime.

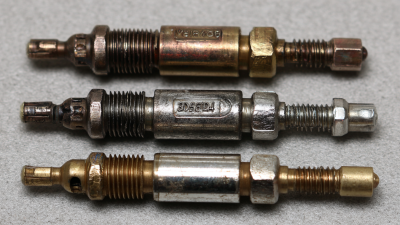

Comparison of Semi-Synthesis Lubricant Properties for Air Compressors

Assessing Operating Conditions and Environment for Lubricant Selection

When selecting a semi-synthesis lubricant for air compressors, evaluating the operating conditions is crucial. Different applications generate unique heat and pressure levels. For instance, high-speed operations may require a lubricant that withstands intense friction. Failure to choose appropriately can lead to reduced efficiency.

Environmental factors also play a role in lubricant selection. High humidity can promote oxidation. Hot outdoor conditions may thin out lubricants quickly. It's important to think about your compressor's work environment. Some users overlook these details. The wrong choice can easily lead to breakdowns, costing time and money.

Beyond technical specifications, understanding the lubricant's composition is key. Semi-synthetic options are popular for their balance between mineral and synthetic properties. However, not all semi-synthetic lubricants perform the same way. Some might not offer adequate protection under extreme conditions. It's a challenge to find the perfect match. Careful consideration of your specific needs will guide you toward the right lubricant choice.

Comparing Costs and Benefits of Semi-Synthesis Lubricants

When considering semi-synthesis lubricants for air compressors, cost and benefits are crucial factors. These lubricants often provide enhanced performance compared to conventional options. They can improve efficiency and potentially extend the life of your compressor, saving on replacement costs.

However, the initial price can be higher. This might raise questions. Is the added cost worth it? Evaluating the operational efficiency and maintenance frequency can provide clarity. Some users notice less wear on components, which leads to fewer repairs. The decision may boil down to how often the compressor runs and its workload.

Another aspect to think about is compatibility with existing systems. Not all semi-synthetic lubricants fit every model. Researching specific requirements will help avoid issues. Many users report mixed feelings; some may encounter performance drops after a switch. Keeping records of oil changes and performance before and after can offer valuable insights.

Tips for Regular Maintenance and Lubricant Replacement

Regular maintenance is essential for the longevity of your air compressor. Check the lubricant levels frequently. Low lubricant can lead to increased friction and overheating. Ensure that the lubricant is clean and free from contaminants. Dirty lubricant can damage internal components.

Changing the lubricant on schedule is crucial. Follow the manufacturer's guidelines for replacement intervals. However, you might notice that real-world conditions often differ. Your compressor could require more frequent changes in a dusty environment. Always observe the lubricant condition during maintenance checks.

Documenting each maintenance event can also help track patterns. If you see frequent lubricant failure, it’s a sign of underlying issues. This requires immediate attention. Think about the balance between cost and optimal performance. It's easy to overlook small details, but they matter. Each drop of lubricant contributes to the overall efficiency of your air compressor.

Analysis of Market Trends and Performance in Screw Air Compressors: A Focus on the ACPL-516 Model

In the realm of screw air compressors, the ACPL-516 model stands out due to its robust performance driven by advanced technological features. A significant factor contributing to its efficiency lies in the use of fully synthetic lubricants, such as PAG and POE. These high-performance additives ensure excellent oxidation stability, allowing the compressor to maintain optimal operations across varying temperatures. As a result, users can expect minimal carbon deposits and sludge formation, which often hinder the performance of conventional lubrication systems.

Moreover, the longevity of the lubricants used in models like the ACPL-516 is impressive, with a working lifespan of 8000 to 12000 hours under standard operating conditions. This durability is particularly advantageous for applications involving high-temperature environments, where traditional lubricants may falter. The effective lubrication and protection against wear that these synthetic oils provide not only enhance the compressor's operational reliability but also prolong its overall lifespan, making it an intelligent choice for those in industries reliant on consistent air compressor performance.

FAQS

: Regular exercise improves mood and energy levels. It boosts overall health and helps maintain a healthy weight.

Begin with simple activities like walking. Gradually increase the intensity and duration of your workouts.

Missing a workout is normal. Reflect on what caused it, and try to reschedule or adjust your plan.

Nutrition plays a crucial role in fitness. Balanced meals fuel your workouts and aid in recovery.

Soreness is common after intense workouts. Rest and gentle stretching can help ease the pain.

Set realistic goals and track your progress. Surround yourself with supportive people to stay inspired.

Yes, many effective exercises require no equipment. Bodyweight exercises and outdoor activities work well.

Daily exercise is fine, but vary the intensity. Rest is important for recovery and preventing injuries.

Mix up your routine with different activities. Try new sports or join group classes to stay engaged.

Results can take time. Reflect on your routine and diet. Consider seeking advice from fitness professionals.

Conclusion

Choosing the right Semi-Synthesis Lubricant for Air Compressor is crucial for optimal performance and longevity of the equipment. Semi-synthesis lubricants, which combine mineral oils with synthetic additives, offer enhanced lubrication, reduced friction, and better thermal stability. Understanding the key features of these lubricants, such as viscosity and temperature stability, is vital when evaluating the performance requirements of your specific air compressor model.

When selecting a lubricant, consider compatibility with compressor materials to avoid degradation and ensure reliable operation. Additionally, assess the operating conditions—such as temperature and humidity—where the compressor will function to make an informed choice. Cost-effectiveness also plays a role; while semi-synthesis lubricants may present a higher upfront cost, their benefits can lead to lower maintenance and downtime expenses. Regular maintenance and timely lubricant replacement are essential for sustaining performance and protecting the compressor, making it important to adhere to best practices for lubrication.

Related Posts

-

How to Choose the Right Ingersoll Rand Lubricant for Your Equipment Needs

-

Top Strategies for Choosing the Best Lubricant Oil Can for Your Business Needs

-

5 Hidden Benefits of Using Synthetic Lubricant Spray You Never Knew About

-

7 Best Benefits of Using Non Detergent Lubricating Oil for Your Machinery

-

What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

-

How to Select the Right Thread Lubricant for Your Specific Needs