Essential Guide to Choosing the Right Diffusion Pump Oil for Optimal Vacuum Performance

Table of Contents

- Understanding the Role of Diffusion Pump Oil in Vacuum Systems

- Key Properties of Diffusion Pump Oils Impacting Performance

- Comparative Analysis of Synthetic vs. Mineral Diffusion Pump Oils

- Choosing the Right Viscosity for Enhanced Pump Efficiency

- Impact of Contaminants on Diffusion Pump Oil Lifespan and Vacuum Integrity

- Best Practices for Maintaining and Replacing Diffusion Pump Oil

- Enhancing Vacuum Performance: The Role of K Series Diffusion Pump Oil in the Semiconductor Industry - Insights from Recent Market Analysis

- FAQS

- Conclusion

- Related Posts

In today's vacuum tech scene, picking the right diffusion pump oil is super important if you want your system to perform well and stay efficient. From what I've seen in recent industry reports, the quality of the oil you choose actually has a big impact — it affects things like throughput and the final pressure you can achieve in vacuum setups. That’s true whether you're working on semiconductor stuff or doing research in a lab. At Shanghai Jiongcheng Industrial, we totally get how crucial good lubrication solutions are, especially when it comes to high-temperature chain lubricants. Our team’s got solid expertise in compressor and vacuum pump lubricants, backed by cutting-edge technology in R&D and manufacturing. We make sure our oils meet strict standards, so your equipment runs smoothly and lasts longer. As demands in vacuum applications keep growing, it’s more important than ever to select the right diffusion pump oil — it’s not just about performance but also about protecting your gear over the long haul.

Understanding the Role of Diffusion Pump Oil in Vacuum Systems

You know, diffusion pump oil is pretty important if you want your vacuum system to run smoothly. It's basically the fluid that the pump uses to create and keep up the right vacuum conditions — whether you're working in semiconductor fabrication or doing some scientific experiments. I read in the Vacuum Technology and Coating journal that the kind of oil you choose can really make a difference, not just in how well the pump works but also how long it lasts. For example, oils with high thermal stability and low vapor pressure are super helpful because they cut down on backstreaming and keep the vacuum environment clean and clear.

And let's not forget about viscosity — that's a big deal too. Studies show that oils with lower viscosity can help the pump run faster, which means better overall performance. There was this one research from the International Journal of Vacuum Science and Technology that pointed out using the wrong oil might slow things down by up to 30%. That could lead to less effective vacuum levels and mess up your process. So, honestly, understanding what makes a good diffusion pump oil — its qualities and how it works — is key. Picking the right oil isn’t just about efficiency; it also helps your vacuum components last longer. Bottom line: choosing the right oil for your specific setup is a pretty big deal for professionals aiming to get the job done right.

Key Properties of Diffusion Pump Oils Impacting Performance

Picking the right diffusion pump oil honestly makes all the difference if you want your vacuum system to perform well. There are a few key things to keep in mind about these oils that really affect how well they work. For example, viscosity is pretty important — it influences how effectively the pump can trap gas molecules. I came across a report from the Vacuum Technology Association that said oils with lower viscosity tend to give you faster pumping speeds and better overall performance at low pressures. On the flip side, oils with a bit higher viscosity are usually more stable when things heat up.

Another thing to consider is vapor pressure. Basically, you want an oil with low vapor pressure because it reduces the chance of oil backstreaming into your vacuum chamber. Keeping things as clean as possible is especially important if you're doing sensitive work. According to research published in the Journal of Vacuum Science & Technology, oils with vapor pressure below 10^-5 Torr are considered ideal for top-tier applications.

A quick tip: when you're choosing diffusion pump oil, it’s a good idea to think about your system’s specific conditions and maybe do a little analysis first. It’s also smart to keep an eye on the oil’s properties over time — things can degrade, and that could affect performance. And hey, always go for oils from reputable brands. Trust me, it makes a real difference when it comes to keeping your vacuum system running smoothly.

Essential Guide to Choosing the Right Diffusion Pump Oil for Optimal Vacuum Performance

Comparative Analysis of Synthetic vs. Mineral Diffusion Pump Oils

So, when you're trying to pick the right diffusion pump oil, one of the big questions is whether to go for synthetic or mineral oil. Synthetic oils are often made up of specially formulated hydrocarbons, and honestly, they usually beat mineral oils in terms of stability — like, they handle heat better and have lower vapor pressure. I read a recent article in the Vacuum Technology and Coating Journal that said using synthetic oils can actually make your vacuum system last up to 30% longer, which means less downtime and saving some cash on maintenance.

On the flip side, mineral oils tend to be a lot easier on the wallet and are pretty easy to find, so they’re a go-to for many folks. The catch? They tend to have higher vapor pressures, which can cause more outgassing and potential contamination, especially when you're working with ultra-high vacuum setups. According to data from the Journal of Vacuum Science & Technology, in critical applications like semiconductor manufacturing, switching to synthetic oils can cut down particle contamination by about 50%. That’s a pretty big deal.

**Heads up:** Think about what your setup really needs. If you need something that stays stable under heat and keeps outgassing low, going with synthetic oil might be worth the extra bucks—even if it costs more upfront. But if your environment isn’t super demanding, a good quality mineral oil can do the trick without breaking the bank. And, of course, always double-check the manufacturer’s specs and data sheets to make sure you’re choosing the right one for your system. Trust me, a little bit of research goes a long way!

Essential Guide to Choosing the Right Diffusion Pump Oil for Optimal Vacuum Performance

| Oil Type | Viscosity (cSt) at 40°C | Thermal Conductivity (W/m·K) | Operating Temperature Range (°C) | Pump Down Time (Minutes) | Cost per Liter (USD) |

|---|---|---|---|---|---|

| Synthetic Oil | 10 | 0.15 | -30 to 200 | 5 | 150 |

| Mineral Oil | 12 | 0.12 | -20 to 180 | 7 | 50 |

| Silicone Oil | 15 | 0.18 | -50 to 250 | 6 | 200 |

Choosing the Right Viscosity for Enhanced Pump Efficiency

Picking the right viscosity for diffusion pump oil is super important if you want your vacuum system to perform at its best. Basically, viscosity is just a fancy way of saying how much a fluid resists flowing — and that directly affects how well the oil moves around inside the pump. If you go for a lower viscosity oil, it can cut down on friction and speed things up, but it might not give enough lubrication when things heat up. On the flip side, thicker oils with higher viscosity tend to stay stable longer and protect the pump from wear, but they can slow down the pumping response a bit.

When you're choosing your diffusion pump oil, keep in mind what your vacuum setup needs. For example, if your process is running at high temperatures, you'd probably do better with oils that can handle the heat and stay stable. On the other hand, if you're working in a lab and want quick pumping speeds with less backstreaming, a lower viscosity oil could be your best bet. In the end, it’s all about finding that balance — matching the oil’s viscosity to what your application demands, so your pump works efficiently and lasts longer.

Impact of Contaminants on Diffusion Pump Oil Lifespan and Vacuum Integrity

You know, how long your diffusion pump oil lasts really depends a lot on what's in it. If contaminants like dust or tiny metal shavings sneak in, they can cause all sorts of problems, like messing up the vacuum quality and hampering the overall performance. When foreign particles get into the oil, they can kick off reactions that produce harmful byproducts. These byproducts can make the oil thicker over time, reduce its ability to handle heat, and eventually lead to the pump not being able to keep up with the vacuum levels it needs. So, honestly, keeping the oil clean is super important if you want your system to run smoothly.

Plus, contaminants don't just come from outside stuff—they can also originate from within the system itself. Things like outgassing from materials inside the vacuum chamber or even oil evaporating can add to the contamination problem. Once that happens, it becomes a bit of a vicious cycle — more contamination leads to more frequent oil changes and repairs, which means more time and money spent. That’s why setting up good filtration systems and sticking to regular maintenance is a smart move. Understanding how the oil, contaminants, and the overall vacuum performance all play together is key to getting the best results and keeping everything running like clockwork.

Best Practices for Maintaining and Replacing Diffusion Pump Oil

Keeping your diffusion pump oil in good shape is pretty essential if you want top-notch vacuum performance, especially in industrial setups. It’s one of those things where checking and changing the oil regularly can really make a difference—not just in how well the pump works but also in how long it lasts. I came across a report from the Vacuum Technology and Coating Industry back in 2022, and it said that if you neglect proper maintenance, the pump’s speed can drop by as much as 30%. That’s a pretty big hit, and it obviously messes with the whole vacuum system. So yeah, sticking to a solid maintenance routine isn’t just recommended; it’s kinda necessary.

When it comes to caring for diffusion pump oil, the key is checking its contamination level and temperature pretty often. If the oil turns dark or you spot tiny particles floating around, it’s probably time for a change—these signs can mean it’s thermal degradation or just contaminated. The American Vacuum Society suggests swapping out the oil every 1000 hours of operation, or sooner if you notice it’s getting dirty. Using high-quality oils that are made specifically for diffusion pumps can really help extend how long the pump runs smoothly and keeps performance up. Picking the right oil not only boosts vacuum efficiency but can also save you money in the long run by reducing how often you need to do oil changes and deal with downtime.

Enhancing Vacuum Performance: The Role of K Series Diffusion Pump Oil in the Semiconductor Industry - Insights from Recent Market Analysis

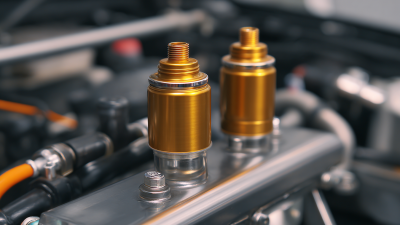

The semiconductor industry relies heavily on vacuum technology, where the efficiency of diffusion pumps is crucial for maintaining clean and controlled environments. Central to this operation is the K Series Diffusion Pump Oil, specifically designed to enhance vacuum performance. Recent market analyses have highlighted its superior thermal stability and lower vapor pressure, characteristics that directly contribute to improved pump efficiency and longevity. These properties allow for a more stable vacuum environment, which is essential for semiconductor fabrication processes that demand stringent cleanliness and precision.

Moreover, the K Series Diffusion Pump Oil is formulated to meet the rigorous requirements of the semiconductor sector. While typical values of its performance are provided, it is important to recognize that actual data may fluctuate within the range allowed by established quality standards. This variability underscores the importance of selecting high-quality pump oil that consistently meets performance expectations. Manufacturers in the semiconductor industry benefit from utilizing K Series Diffusion Pump Oil, ensuring optimal operation of their equipment while maximizing the quality and yield of their semiconductor products.

FAQS

: Synthetic diffusion pump oils offer superior thermal stability and lower vapor pressure, leading to extended operational life and reduced maintenance costs. Mineral oils are more affordable and accessible but have higher vapor pressures that can cause greater outgassing in ultra-high vacuum environments.

Synthetic oils can decrease particle contamination levels by up to 50% in critical environments, making them a better choice for maintaining clean conditions in high-stakes applications such as semiconductor manufacturing.

Consider the specific requirements of your application, such as thermal stability and outgassing. If these factors are critical, synthetic oils are ideal despite their higher cost. For less demanding setups, high-quality mineral oils can be an effective and economical choice.

Viscosity affects fluid resistance to flow, which directly impacts oil circulation within the pump. Lower viscosity oils enhance pumping speed but may insufficiently lubricate at higher temperatures, while higher viscosity oils provide better protection but can slow response times.

The American Vacuum Society suggests replacing diffusion pump oil every 1000 operational hours or when substantial contamination is detected to maintain peak vacuum performance.

Oil should be replaced when it becomes discolored or contains visible particulates, indicating thermal degradation or contamination.

Improper maintenance can result in a reduction of pumping speed by up to 30%, significantly hindering vacuum system performance.

Regularly check contamination levels and temperature, adhere to a replacement schedule, and utilize high-quality oils designed specifically for diffusion pumps to extend service life and ensure optimal performance.

Choosing the correct oil enhances vacuum performance, reduces costs associated with frequent oil changes, and minimizes system downtimes, leading to overall improved operational efficiency.

Conclusion

In

Related Posts

-

Understanding the Importance of Vacuum Pump Lubricants for Optimal Performance

-

Unlocking Industry Potential at the 138th China Import and Export Fair with Becker Vacuum Pump Lubricant

-

7 Best Craftex Dust Collector Reviews for Efficient Industrial Use

-

What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

-

Essential Guide to Choosing the Right Dust Collector Spare Parts for Your Industry

-

How to Choose the Best Semi Synthesis Lubricant for Your Air Compressor

Blog Tags: