Exploring the Future: What Makes Ionic Liquid Compressors a Game-Changer in Industry?

Table of Contents

- The Rise of Ionic Liquid Compressors: An Overview of Their Industry Impact

- Key Advantages of Ionic Liquid Compressors Over Traditional Technologies

- Sustainability and Energy Efficiency: The Green Edge of Ionic Liquid Solutions

- Innovative Applications of Ionic Liquid Compressors Across Various Sectors

- Future Trends: How Ionic Liquid Technology is Shaping the Compressor Market

- Challenges and Research Directions in Developing Ionic Liquid Compressors

- FAQS

- Conclusion

- Related Posts

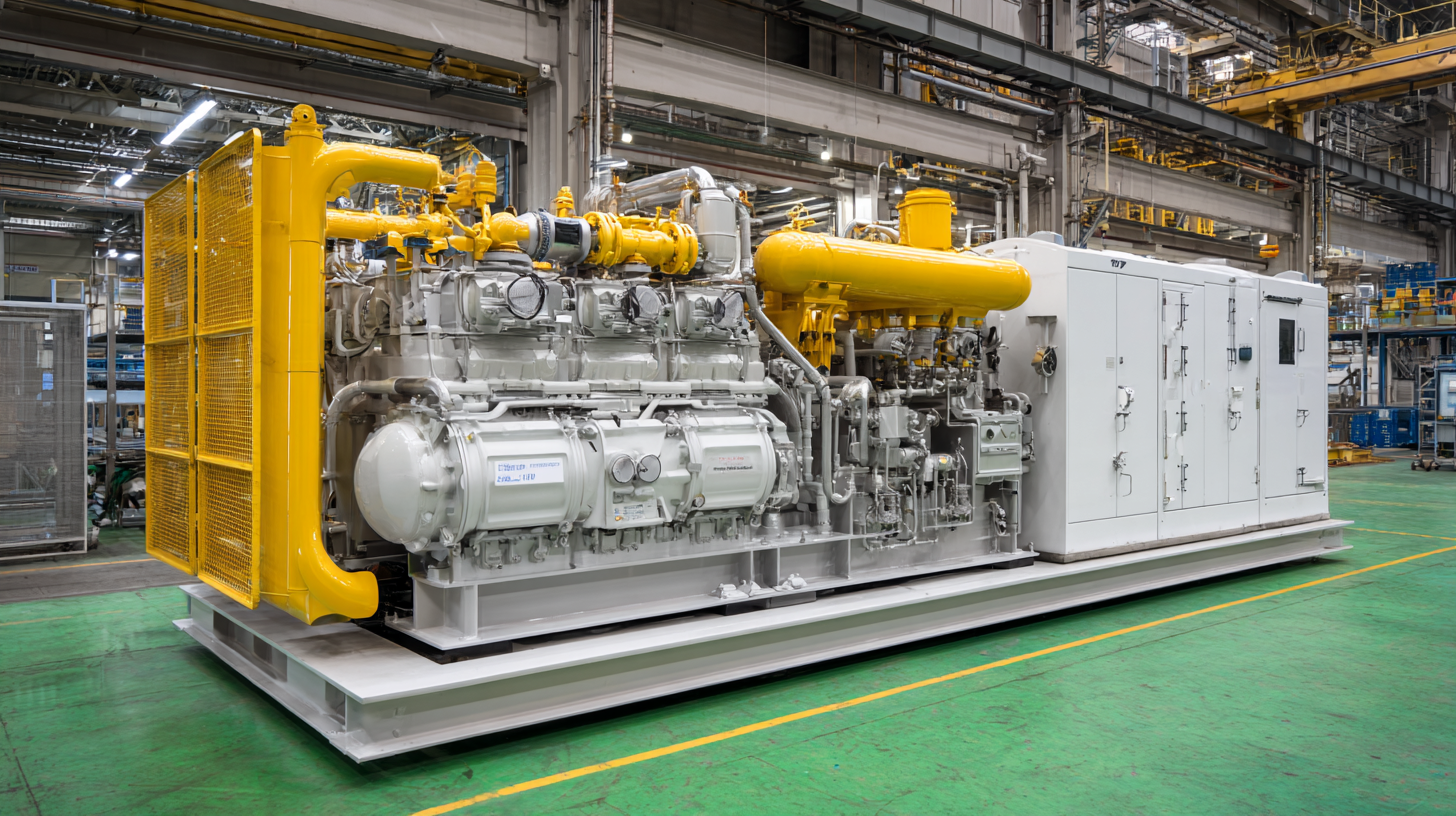

As industries keep pushing for better efficiency and sustainability, adopting new technologies really becomes a game-changer. One of the coolest breakthroughs lately is the Ionic Liquid Compressor—it's honestly a real game-changer when it comes to compression tech. Recent studies show that using ionic liquids in compressors can boost energy efficiency by up to 30%, and it also helps cut down greenhouse gas emissions. That’s a big win for companies like Shanghai Jiongcheng Industrial Co., Ltd. They’re all about providing total lubrication solutions, including special lubricants for compressors, vacuum pumps, and refrigeration systems. By staying on top of the latest tech and running thorough quality checks, they aim to make lubricants perform even better, which in turn makes the Ionic Liquid Compressors run smoother across all kinds of industrial setups.

The Rise of Ionic Liquid Compressors: An Overview of Their Industry Impact

As industries keep advancing, one of the coolest breakthroughs lately has been ionic liquid compressors. These things use ionic liquids — which basically have some pretty awesome traits like low volatility and top-notch thermal stability — making them super efficient for all sorts of industrial uses. The best part? They can handle really extreme conditions, so they often outshine the old-school systems, helping save energy and cut down on operating costs. It’s a win-win: better sustainability and more reliable performance in tough environments.

At Shanghai Jiongcheng Industrial Co., Ltd., we totally understand how vital it is to have the right lubrication solutions to keep these high-tech compressors running smoothly. That's why we focus on creating specialized lubricants, especially for compressors and high-temp situations. We put a lot of effort into quality and research, making sure our products can take on the demands of modern industry while helping your equipment work at its best.

A quick tip: to get the most out of your ionic liquid compressors, make sure you’re doing regular maintenance on your lubricants to avoid failures. Keep the operating temperatures in check to maintain efficiency, and always use lubricants that are designed specifically for ionic liquid technology. Trust me, these little steps can really boost performance and last longer, saving you headaches down the line.

Exploring the Future of Ionic Liquid Compressors

This chart indicates the potential impact levels of Ionic Liquid Compressors across various key metrics, showcasing their promise in transforming industry practices.

Key Advantages of Ionic Liquid Compressors Over Traditional Technologies

You know, ionic liquid compressors are really starting to shake things up in the industrial world. They have some pretty cool advantages that set them apart from the usual compressors we’re used to. For starters, their low vapor pressure and high thermal stability make them perfect for running efficiently in all sorts of conditions—kind of like the Swiss Army knives of compression tech. Recent research even suggests that these compressors can cut down energy use by up to 30%, which is a big deal for making operations more sustainable and eco-friendly.

And get this—when it comes to hydrogen infrastructure, ionic liquid compressors could be a game changer. As everyone’s pushing harder for hydrogen energy, these liquids can handle really tough conditions and help make storage and transport way more efficient. That means faster, cheaper hydrogen production—reports are saying costs might drop by about 15%. All of this could really help more industries adopt hydrogen as a cleaner energy source. Honestly, it’s exciting to see where this tech is headed—ionic liquid compressors are set to take efficiency and performance to a whole new level in the industry.

Sustainability and Energy Efficiency: The Green Edge of Ionic Liquid Solutions

Ionic liquid compressors are really shaking things up across different industries. They bring some pretty cool perks that help out with sustainability and saving energy. Unlike the old-school compressors that depend on nasty refrigerants, these liquids are non-volatile and can handle temperature changes pretty well, so they’re easier on the environment. Plus, they can run at lower pressures and temperatures, which means they use less energy overall. That’s great news for businesses trying to cut costs and shrink their carbon footprint at the same time. Honestly, they seem like an attractive option if you wanna boost your green credentials.

It’s also worth mentioning that using ionic liquids fits perfectly into the global push for greener, more sustainable practices. Companies are feeling more pressure than ever to go eco-friendly, and ionic liquid compressors are a pretty solid way to make that happen. The best part? They can be customized for different needs, which helps cut down on waste and makes systems more efficient. By jumping on board with ionic liquids, industries aren’t just ticking boxes for environmental regs—they’re also fostering innovation that supports sustainability in the long run. Basically, they’re setting a new standard for energy-efficient tech that’s hard to ignore.

Innovative Applications of Ionic Liquid Compressors Across Various Sectors

Ionic liquid compressors are honestly a pretty exciting breakthrough in a bunch of industrial fields. What makes them so cool is their unique properties and how flexible they are. Basically, they use ionic liquids—salts that stay liquid at room temperature—which means they can handle a wide range of temperatures without breaking a sweat. That’s a big deal, especially in industries like pharmaceuticals, where keeping things at just the right temperature is super important for sensitive processes.

You'll also find these compressors making waves in the chemical processing world. Their ability to safely work with volatile stuff means things run smoother and safer, cutting down on the chances of leaks or accidents. Plus, with their low vapor pressure, they’re better for the environment too. And when it comes to energy and sustainability, ionic liquid compressors are really shaking things up in CO2 capture tech. They help make carbon management way more efficient. As industries keep pushing for greener and more sustainable options, these compressors are opening up new pathways to cut emissions and make better use of resources. Overall, they’re paving the way toward cleaner, smarter industrial processes.

Future Trends: How Ionic Liquid Technology is Shaping the Compressor Market

As the compressor market keeps changing and evolving, ionic liquid technology is really stepping into the spotlight, bringing a whole new level of efficiency and eco-friendliness. Unlike your old-school lubricants that tend to break down when things heat up, ionic liquids are super stable even at high temperatures. That means compressor systems can handle more extreme conditions without wearing out or losing performance. I recently read a report in the International Journal of Refrigeration—pretty interesting stuff—that says using ionic liquids can boost energy efficiency by up to 20%. Basically, it’s a game-changer for industries that want to cut down on energy use without sacrificing performance.

Here at Shanghai Jiongcheng Industrial Co., Ltd., we’re really excited about this innovation. We focus on creating integrated lubrication solutions that are customized for different applications, whether it’s compressors, vacuum pumps, or other machinery. Our cutting-edge tech and strict quality checks help ensure our products stand up to the toughest demands of today’s industry. Embracing ionic liquid technology fits perfectly with our mission to deliver high-performance lubricants that not only help your equipment run smoother and more efficiently but also contribute to a more sustainable future. As things shift and new trends come in, staying ahead with these advanced lubricants is pretty much essential for any organization eager to stay competitive in this eco-conscious, tech-driven world.

Challenges and Research Directions in Developing Ionic Liquid Compressors

The development of ionic liquid compressors is really shaking things up in the industrial world, but of course, there are quite a few hurdles that researchers need to figure out. One big thing is how stable these ionic liquids are when it gets really hot; their performance can take a hit at high temperatures. I read a report recently from the Global Institute of Chemical Engineering, and it said that ionic liquids tend to lose efficiency once temperatures go over around 200°C. That raises questions about whether they’re really practical for things like power plants or cooling systems.

And then, there’s also the issue of making sure these new liquids play nice with the equipment we already use. Lots of industries currently rely on conventional lubricants and refrigerants, and mixing in ionic liquids might not be so straightforward. The International Refrigeration Institute did some research into this, pointing out that understanding how ionic liquids interact with traditional materials—like how well they dissolve and their viscosity—is super important if we want everything to work smoothly. The key might be designing custom ionic liquids tailored for specific needs; if we get that right, it could unlock some serious gains in efficiency and make industrial processes more sustainable overall.

FAQS

: Ionic liquid compressors are advanced compression systems that utilize ionic liquids, which are known for their low volatility and excellent thermal stability, making them highly efficient for various industrial applications.

Ionic liquid compressors offer key advantages such as improved energy efficiency, reduced energy consumption by up to 30%, enhanced performance in extreme conditions, and the ability to support sustainable practices in industries.

Performance can be maximized through regular maintenance of lubrication systems, ensuring optimal operating temperatures, and using compatible lubricants specifically designed for ionic liquid technologies.

Ionic liquid technology can enhance hydrogen storage and transport by withstanding extreme conditions, potentially decreasing hydrogen production costs by up to 15% and facilitating cleaner energy sources.

The thermal stability of ionic liquids allows compressor systems to operate under extreme temperatures without significant degradation, thus maintaining performance and enhancing overall efficiency.

Shanghai Jiongcheng Industrial Co., Ltd. focuses on developing specialized lubricants for ionic liquid compressors, ensuring high performance and efficiency through advanced lubrication solutions tailored for industrial applications.

Incorporating ionic liquids into compressor systems can enhance energy efficiency by up to 20%, making them attractive for industries focused on reducing energy consumption.

Future trends suggest that the compressor market will increasingly embrace ionic liquid technology for improved efficiency, performance, and sustainability, aligning with environmental considerations and technological advancements.

Important maintenance tips include regular checks on lubrication systems, ensuring optimal operating temperatures, and using compatible lubricants designed for ionic liquid technologies.

The integration is crucial because it supports higher operational efficiency, addresses sustainability concerns, and helps industries remain competitive in an evolving market defined by environmental consciousness and technological progression.

Conclusion

Ionic liquid compressors are really turning heads in the industrial world. They’re a game-changer compared to the old-school compressors we used to rely on. Thanks to their special properties, they boost efficiency, sip less energy, and are much kinder to the environment. That makes them a pretty cool, sustainable option for a bunch of different uses. In fact, we're seeing these compressors shake up industries from refrigeration to vacuum tech, offering fresh, innovative solutions that focus on both top-notch performance and eco-friendliness.

Now, if we look at companies like Shanghai Jiongcheng Industrial Co., Ltd., which already do a great job with high-quality lubrication products, adding ionic liquid compressor tech could be a real win. It fits nicely with their existing lineup, like their compressor lubricants and vacuum pump oils. By tapping into advanced chemistry and R&D, the whole industry can better tackle the demands of today’s applications, while also thinking ahead to future challenges and opportunities for ionic liquid compressors. Ultimately, blending lubrication tech with ionic liquids could really boost operational efficiency and sustainability across the board — pretty exciting, right?

Related Posts

-

7 Compelling Reasons to Choose the Right Cyclone Dust Collector for Your Business

-

2025 Market Insights: Best Reliant Dust Collector Model 720 as a Game-Changer for Global Procurement Trends

-

Innovative Applications of Jet Dust Collector Dc-1200 in Modern Industry

-

Innovative Applications of One Unit Dust Collector Together in Diverse Industries

-

Essential Checklist for Choosing the Right Cyclone Dust Collector Supplier

-

Choosing the Right Manufacturer for Best Micro Air Dust Collectors and Key Features to Compare

Blog Tags: