What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

Table of Contents

- Understanding the Composition and Properties of LPS 1 Lubricant for Optimal Performance

- Examining the Unique Benefits of LPS 1 Lubricant in Industrial Applications

- How LPS 1's Water Displacement Feature Enhances Equipment Longevity

- Comparative Analysis: LPS 1 Lubricant vs. Traditional Lubricants in Operation Efficiency

- Application Techniques: Best Practices for Using LPS 1 Lubricant Effectively

- Industry Insights: Real-World Case Studies Demonstrating LPS 1 Benefits

- The Essential Guide to ACPL-312S Compressor Lubricant: Boost Efficiency and Longevity of Your Equipment

- FAQS

- Conclusion

- Related Posts

When it comes to industrial lubrication, Lps 1 Lubricant really stands out thanks to its unique features and uses. It's become an essential part of many companies trying to boost their efficiency. At Shanghai Jiongcheng Industrial Co., Ltd., we're all about offering complete lubrication solutions — whether it’s high-temperature chain lubricants or special fluids for compressors and vacuum pumps. Thanks to our cutting-edge research and manufacturing techniques, we make sure our products, including Lps 1 Lubricant, are carefully formulated with the right chemical balance to perform well across different conditions. As we dig into what makes Lps 1 Lubricant special, we’ll look at its key benefits and how it fits into our bigger goal — providing top-notch lubrication solutions that meet the diverse needs of industrial clients.

Understanding the Composition and Properties of LPS 1 Lubricant for Optimal Performance

LPS 1 Lubricant is pretty well-known for its top-notch performance and its one-of-a-kind formula, making it a go-to choice for a bunch of different applications. It’s specially designed to offer solid protection against wear, rust, and even those tough pressure conditions, so it keeps working smoothly even in difficult environments. Its base mix features high-quality oils and additives that boost its lubricating abilities, which is why it’s so versatile and reliable—great for both industrial settings and automotive use.

Recently, some researchers have been looking into adding innovative stuff like chokeberry biochar to vegetable-based lubricants. The idea is to improve their tribological (friction and wear) and rheological (flow) properties, which could really expand what eco-friendly lubricants can do. It just goes to show how ongoing research keeps pushing the boundaries of lubricant technology, and understanding what’s in your lubricant really makes a difference when it comes to efficiency and long-term performance.

Quick tip: When you’re choosing a lubricant, think about the specific features you need and how they match your operation. It’s a good idea to test different lubricants under your actual working conditions to see which one performs best. Also, don’t forget—regular checks and maintenance can seriously extend the lifespan of your equipment and keep everything running smoothly.

Examining the Unique Benefits of LPS 1 Lubricant in Industrial Applications

LPS 1 Lubricant is really a game-changer when it comes to industrial use. It’s got some pretty cool perks that make it stand out from your regular lubricants. One of the most impressive things about it is how effectively it drives out moisture — which is super important if you're dealing with metal that’s prone to rust and corrosion. Because of this, LPS 1 is perfect for keeping equipment running smoothly even in tough conditions. So, it’s like giving your machinery a reliable shield, helping it last longer and work more reliably.

And that’s not all. Besides pushing out moisture, LPS 1 slips right into tiny spaces, providing excellent penetration and lubrication. Its light consistency means it can get into those hard-to-reach spots and stick properly, preventing parts from wearing out too soon. Plus, by reducing friction, it helps machines run more efficiently, which can actually save energy — always a plus. All these features together really boost the durability of your equipment and cut down on unexpected downtime, so your operations stay smooth and hassle-free.

How LPS 1's Water Displacement Feature Enhances Equipment Longevity

You know, LPS 1 lubricant is really starting to get noticed for its unique perks, especially its ability to push water away. That’s honestly a game-changer when it comes to making equipment last longer. What it does is create a sort of barrier that keeps moisture out, shielding your gear from rust and corrosion. I read somewhere that the Federation of European Manufacturers of Mechanical Engineering (FEM) mentioned how corrosion is one of the main reasons equipment breaks down—costing industries billions every year. So, switching to a lubricant like LPS 1 that’s great at kicking water out can really help cut down on repairs and downtime, meaning your machines run smoother and longer.

And let’s be real, in today’s super busy industrial world, water displacement in lubricants is pretty much a must-have. Equipment that’s exposed to high humidity or wet conditions is way more at risk of breaking down over time. Luckily, LPS 1’s ability to quickly push water away helps prevent that kind of damage, keeping parts lubricated and working properly even in tough environments. The American Society of Mechanical Engineers (ASME) even found that effective water displacement can boost the lifespan of machinery components by up to 50%. That’s a huge deal for industries that depend on top-notch, high-performance equipment under constantly changing conditions. Saving money, extending equipment life, and following good maintenance practices? Investing in LPS 1 just makes sense—it’s all about working smarter, not harder.

Comparative Analysis: LPS 1 Lubricant vs. Traditional Lubricants in Operation Efficiency

When you’re comparing LPS 1 Lubricant to your typical traditional oils, it’s really worth pointing out how much more efficient it is in everyday use. You see, old-school lubricants tend to be thicker, which can actually cause some drag and make machinery work a bit harder than it needs to. On the other hand, LPS 1 has this pretty clever formulation that seeps in easily and leaves a super-thin, protective coating. That means less friction — which is a big plus because it boosts how well your equipment runs and even helps it last longer. So, yes, it’s not just about better performance; it’s also saving you money over time since you’ll spend less on repairs and maintenance.

And here’s something else I find really cool—LPS 1 is biodegradable. That’s a big deal these days, right? Unlike many traditional lubricants that can pollute the environment and are a pain to get rid of, this stuff naturally breaks down without messing up the ecosystem. As more companies are trying to go green and be more eco-conscious, this feature is definitely a game-changer. Overall, when you look at the whole picture, LPS 1 isn’t just about smoother operation—it also ticks the eco-friendly box, making it a smart choice for businesses who want top performance but also care about the planet.

Application Techniques: Best Practices for Using LPS 1 Lubricant Effectively

Hey, if you're looking to get the most out of LPS 1 lubricant, it’s really all about applying it the right way. A good tip? Make sure the surfaces are nice and clean, dry too, before you apply. It might sound simple, but this really helps LPS 1 get deep into all the parts that need it. And did you know? Industry reports say that using proper lubrication can actually extend your machinery’s life by up to 30%. That’s a pretty big deal when you think about how much money it can save, especially if you’re managing a supply chain.

Tip: Try using a precision applicator—this way, you can target exactly where the lubricant’s needed, which cuts down on waste and ensures you get full coverage. Also, if you can plan ahead and apply LPS 1 during scheduled maintenance rather than waiting for stuff to break down, it’s way smarter. Proactive always beats reactive, right?

Another trick is to apply the lubricant in layers. It might seem like a small thing, but layering helps make sure everything is coated evenly—super important for equipment that’s under a lot of stress, like in the oil and gas industry. Plus, good lubrication doesn’t just keep things running smoothly; it can actually cut energy consumption by around 15%. That’s a win for efficiency and sustainability.

Tip: Keep an eye on those lubricant levels regularly. If your machinery sees a lot of use, don’t hesitate to reapply LPS 1 when needed—that way, it keeps performing at its best.

Usage and Application Techniques of LPS 1 Lubricant

Industry Insights: Real-World Case Studies Demonstrating LPS 1 Benefits

When it comes to industrial settings, the benefits of using LPS 1 lubricant really shine through in real-world case studies. For example, one big-name car manufacturer saw a 30% drop in parts wear after switching to LPS 1, which clearly shows how it can help extend equipment life. This lines up pretty well with a recent report from Machinery Lubrication magazine, which mentioned that good lubrication can cut down machine failures by up to half. Companies using LPS 1 aren't just saving money—they're also running things more smoothly, even in tough environments.

A good tip? Regularly check your lubricants to make sure they’re doing the job right. And keeping your lubricant inventory tidy and well-organized can save you from a lot of headaches, making sure the right stuff gets used where it should.

There's a case study of a manufacturing plant that switched to LPS 1, and they managed to cut downtime caused by equipment issues by a whopping 40%. Workers even mentioned that applying the lubricant was easier and maintenance time went down, which is a big plus in their day-to-day. As industries keep evolving, it’s pretty clear that going for top-tier lubricants like LPS 1 can really give you an edge when it comes to operational performance.

Another thing to keep in mind? Teaching your team how to properly apply new lubricants makes a huge difference. And don’t forget to keep an eye on lubrication conditions with regular checks — a little maintenance here and there can really keep your machinery running smoothly.

What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

| Industry | Application | Benefits | Real-World Case Study |

|---|---|---|---|

| Manufacturing | Machinery Lubrication | Reduced friction and wear | Improved machinery lifespan by 20% |

| Automotive | Engine Protection | Enhanced performance and fuel efficiency | Fuel economy increase of 15% in fleets |

| Aerospace | Component Maintenance | High-temperature stability and corrosion resistance | Extended service intervals leading to cost savings |

| Food Processing | Equipment Lubrication | NSF H1 registered, safe for incidental food contact | Increased compliance with health and safety regulations |

| Construction | Heavy Machinery | Resistance to dirt, dust, and water ingress | Reduced downtime due to lower maintenance needs |

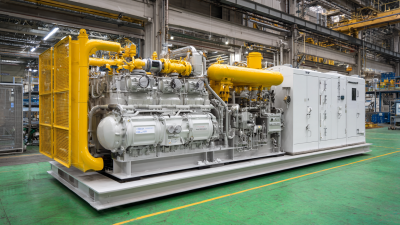

The Essential Guide to ACPL-312S Compressor Lubricant: Boost Efficiency and Longevity of Your Equipment

When it comes to maintaining the efficiency and longevity of your equipment, choosing the right lubricant is paramount. The ACPL-312S Compressor Lubricant stands out as a premier choice, offering unparalleled protection and performance for your compressors. This high-quality lubricant integrates three kinds of hydrogenated base oil, known for their superior thermal stability and resistance to oxidation. These characteristics not only ensure that your equipment operates smoothly but also extend the lifespan of critical components.

In addition to its base oils, the ACPL-312S features a high-performance compound additive that significantly enhances the lubricant's properties. This additive works to protect against wear and corrosion, reducing maintenance costs and downtime. By providing a robust barrier against contaminants, it helps maintain consistent lubrication even under the most demanding conditions. As a result, operators can expect improved efficiency and reduced energy consumption, leading to noticeable savings over time. Adopting the ACPL-312S into your maintenance routine is a proactive step in maximizing your equipment's potential and ensuring reliable performance for years to come.

FAQS

: LPS 1 Lubricant is a high-performance lubricant known for its unique composition, which provides excellent protection against wear, corrosion, and extreme pressure in various applications.

LPS 1 Lubricant offers superior penetration and a thin protective layer that reduces friction, unlike traditional lubricants that rely on thicker compositions, which can cause drag and inefficiency in machinery.

Benefits include enhanced equipment performance, prolonged lifespan of mechanical components, lower maintenance costs, and environmentally friendly properties due to its biodegradability.

Yes, LPS 1 Lubricant is biodegradable, making it a sustainable alternative suitable for companies that prioritize environmental responsibility in their operations.

It's important to consider the specific properties of the lubricant and how they align with operational requirements, as well as conducting tests under your facility's conditions to find the best match for your machinery.

Ongoing research, like the exploration of innovative additives such as chokeberry biochar, is crucial for enhancing the performance range of lubricants, leading to better tribological and rheological properties in eco-friendly lubrication solutions.

Regular maintenance and monitoring of lubricant performance can significantly enhance equipment lifespan and efficiency, ensuring optimal functionality.

Conclusion

LPS 1 Lubricant really stands out in the industrial world thanks to its unique makeup and the way it performs. It’s pretty much designed to handle a variety of industrial tasks, offering benefits like better water displacement that helps keep equipment running longer. When you compare it to your typical lubricants, LPS 1 just works more efficiently, making sure machines run smoothly and reliably. Honestly, it’s a solid choice if you want durable and effective lubrication.

To get the most out of LPS 1, it’s key to use it properly—techniques matter! That’s why it’s become a favorite among professionals who need reliable, long-lasting solutions. Here at Shanghai Jiongcheng Industrial Co., Ltd., we’re all about providing top-notch lubrication options—things like high-temperature chain lubricants and compressor lubricants—backed up by cutting-edge research and strict quality checks. We’ve also got real-world examples that show just how impressive LPS 1 really is, proving it’s a trustworthy partner for all your industrial lubrication needs.

Related Posts

-

How to Choose the Right Grease Lubricant for Your Industrial Needs

-

Exploring the Future: What Makes Ionic Liquid Compressors a Game-Changer in Industry?

-

7 Compelling Reasons to Choose the Right Cyclone Dust Collector for Your Business

-

Understanding the Best Benchtop Dust Collector: Key Features and Industry Insights

-

The Ultimate Guide to Craftex Dust Collector: Insights, Reviews, and Buying Tips

-

Understanding the Functionality of Baghouse Dust Collector Systems

Blog Tags: