Why Use Synthesis Lubricant For Air Compressor to Enhance Performance and Longevity

Table of Contents

- Benefits of Synthesis Lubricants for Air Compressors

- Impact on Performance: How Synthesis Lubricants Improve Efficiency

- Enhancing Longevity: The Role of Synthesis Lubricants in Wear Reduction

- Comparing Synthesis Lubricants to Conventional Oils in Air Compressors

- Best Practices for Using Synthesis Lubricants in Air Compression Systems

- Common Misconceptions About Synthesis Lubricants in Industrial Use

- Optimal Performance and Efficiency: Exploring ACPL-522 Screw Air Compressors Fluid for Industrial Applications

- FAQS

- Conclusion

- Related Posts

In the busy world of industrial stuff, making sure air compressors work well and last long is a big deal. One cool new thing that’s been gaining attention is using Synthesis Lubricant for Air Compressors. It’s not your average oil — these synthetic lubricants are specially designed to stick around longer, protecting the machine from wear and tear, heat damage, and oxidation. Thanks to this, the compressor doesn’t just run smoother, but it also uses energy more efficiently.

Adding Synthesis Lubricant to your compressor can mean less frequent check-ups and less downtime. Because it stays stable and performs well even under tough conditions, your compressor can handle all sorts of workload changes without breaking a sweat. That’s a big win for keeping things running smoothly and boosting overall productivity.

Plus, these lubricants are tough enough to keep things cool and functioning under high temps and pressures — no overdoing it. That’s why more pros are jumping on board with synthetic lubricants to get the most out of their air compressors. Basically, investing in Synthesis Lubricant isn’t just about maintenance — it’s about going the extra mile for operational excellence. As industries evolve, having reliable, efficient equipment is more important than ever. Using these modern lubricants not only helps your compressors perform at their best but also makes them last longer, which means fewer costs in the long run and better productivity overall.

Benefits of Synthesis Lubricants for Air Compressors

Synthesis lubricants are increasingly recognized for their capacity to significantly enhance the performance and longevity of air compressors. Unlike conventional lubricants, synthesis lubricants are manufactured using advanced chemical processes, resulting in a product that exhibits superior thermal stability and lower volatility. According to a report by the National Lubricating Grease Institute, utilizing synthesis lubricants can extend the service life of equipment by up to 30%, primarily due to their ability to resist breakdown under extreme temperatures and prolonged use.

In addition to improved durability, synthesis lubricants offer enhanced lubrication properties that reduce friction and wear on moving parts within air compressors. A study conducted by the Society of Tribologists and Lubrication Engineers indicated that the use of synthesis lubricants can decrease energy consumption by approximately 5-15%, which translates to notable cost savings for operators over time. These lubricants also provide better protection against rust and corrosion, ensuring that compressor components maintain their integrity and efficiency for longer periods.

By switching to synthesis lubricants, users can achieve a more reliable air compressor operation, ultimately resulting in better output and decreased maintenance needs.

Impact on Performance: How Synthesis Lubricants Improve Efficiency

Synthesis lubricants play a crucial role in enhancing the efficiency of air compressors. Unlike traditional lubricants, synthetic options are engineered to withstand a broader range of temperatures and pressures, which is particularly beneficial in high-demand applications. This resilience leads to a consistent viscosity, ensuring that lubrication remains effective under fluctuating operational conditions. Consequently, air compressors equipped with synthetic lubricants experience reduced friction and wear, allowing them to operate more smoothly and efficiently.

Moreover, the superior cleaning properties of synthesis lubricants contribute to improved performance. These lubricants effectively remove contaminants and deposits that can accumulate within the compressor, which, if left untreated, can hinder airflow and lead to overheating. By maintaining cleaner internal components, synthesis lubricants ensure optimal thermal regulation and air quality. This results in a significant enhancement in the overall operational efficiency of the compressor, translating to lower energy consumption and a longer lifespan for the equipment.

Enhancing Longevity: The Role of Synthesis Lubricants in Wear Reduction

Synthesis lubricants play a crucial role in enhancing the longevity of air compressors by significantly reducing wear. Traditional lubricants can break down under high temperatures and pressures, leading to increased friction and wear on critical components. In contrast, synthesis lubricants are formulated with advanced additives that provide superior stability, ensuring they maintain their protective properties over extended periods. This not only helps to minimize wear on moving parts but also extends the maintenance intervals for the equipment, reducing downtime and operational costs.

Moreover, synthesis lubricants create a more efficient operating environment within the air compressor. By forming a consistent protective film, they effectively reduce metal-to-metal contact, which can be a primary source of wear and tear. This protective layer allows for smoother operation with lower energy consumption, ultimately leading to improved performance. The reduced wear not only prolongs the life of individual components but also enhances the overall durability of the air compressor system, allowing for greater reliability in demanding applications. As a result, the use of synthesis lubricants is an investment in the long-term efficiency and durability of air compressor equipment.

Comparing Synthesis Lubricants to Conventional Oils in Air Compressors

When considering the lubrication needs of air compressors, the choice between synthetic lubricants and conventional oils plays a critical role in determining performance and longevity. Synthetic lubricants, manufactured through advanced chemical processes, offer superior thermal stability and a reduced tendency to oxidize compared to traditional mineral oils. This leads to improved lubrication under high temperatures and prolonged intervals between oil changes. As a result, synthetic options often translate to lower operational costs and less frequent maintenance, benefitting both performance and efficiency.

In addition to their thermal properties, synthetic lubricants exhibit enhanced fluidity, particularly in cold weather conditions. This means they can better reduce friction during the initial startup phase, promoting quicker lubrication of the moving parts. In contrast, conventional oils might thicken in cooler temperatures, leading to potential wear during the critical moments of operation. Furthermore, synthetic oils generally possess additives that resist foam formation, keep dirt in suspension, and combat wear more effectively than their conventional counterparts, ensuring that the air compressor runs smoothly and reliably over its lifespan.

Best Practices for Using Synthesis Lubricants in Air Compression Systems

When using synthetic lubricants in air compression systems, it is essential to follow best practices to maximize their benefits. First and foremost, choose the right lubricant type suited for your specific compressor model and operating conditions. This ensures optimal performance and protection against wear and tear. Additionally, regular monitoring of lubricant levels and quality is crucial. Contaminants can significantly diminish lubricant effectiveness, leading to increased friction and potential damage to the compressor. Scheduled maintenance checks will help in identifying any issues before they escalate.

Another significant aspect is the proper storage and handling of synthetic lubricants. Keep lubricants in their original containers, sealed tightly, and stored in a cool, dry place to prevent contamination. When adding lubricant to the compressor, make sure the components are clean to avoid introducing dirt or debris into the system.

Tips: Always refer to the compressor's manual for specifications on lubricant viscosity and change intervals. Also, consider implementing a lubricant analysis program to assess lubricant condition and determine ideal replacement times. This proactive approach can help optimize your compressor's lifespan and performance.

Performance Comparison of Synthesis vs. Conventional Lubricants in Air Compressors

Common Misconceptions About Synthesis Lubricants in Industrial Use

The use of synthesis lubricants in industrial settings, particularly in air compressors, often comes with a variety of misconceptions that can hinder their adoption. One prevalent myth is that synthetic lubricants are merely a more expensive alternative to conventional oils without any significant benefits. In fact, while the upfront cost may be higher, the enhanced performance and extended machinery life can lead to lower overall operating costs. Synthetic lubricants offer superior stability at high temperatures and resist oxidation, which can drastically reduce the frequency of oil changes and protect the compressor from wear and tear.

Another common misunderstanding is the belief that synthetic lubricants are not compatible with older equipment. Many operators fear that switching to a synthetic lubricant could lead to leaks or reduced efficiency in legacy systems. However, synthetic lubricants are formulated to meet or exceed the requirements of traditional oils and often come with additives that can clean and protect older machinery. By addressing these misconceptions, industries can make informed decisions that enhance the longevity and reliability of their air compressors while reaping the benefits of modern lubrication technology.

Why Use Synthesis Lubricant For Air Compressor to Enhance Performance and Longevity - Common Misconceptions About Synthesis Lubricants in Industrial Use

| Misconception | Truth | Benefit of Synthesis Lubricants |

|---|---|---|

| Synthesis lubricants are too expensive | Higher upfront cost is offset by longer life and reduced downtime | Improved equipment efficiency and longevity |

| They can’t handle high temperatures | Many are specifically designed for high-temperature applications | Stable performance at extreme temperatures |

| Synthetic lubricants require frequent changes | They often last longer than conventional oils | Fewer maintenance interruptions and costs |

| Synthesis lubricants are only for high-performance machines | They are beneficial for all types of compressors | Optimized performance across diverse operating conditions |

| They cause more wear than conventional oils | Actually, they provide better protection against wear | Extended machinery life and reliability |

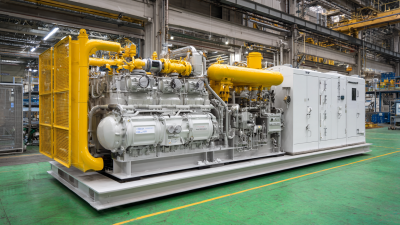

Optimal Performance and Efficiency: Exploring ACPL-522 Screw Air Compressors Fluid for Industrial Applications

In the realm of industrial applications, the choice of fluid plays a pivotal role in ensuring optimal performance and efficiency of screw air compressors. The ACPL-522 series of screw air compressors exemplifies this with its compatibility with fully synthetic fluids, such as PAG and POE, that include high-performance additives designed to enhance operational capabilities. Data from industry reports highlights that the right lubricant can significantly extend the operational lifespan of compressors, with optimal conditions allowing for a working time of 8,000 to 12,000 hours.

These fully synthetic fluids are engineered to provide excellent oxidation stability and high-temperature performance, making them ideal for environments where heat generation is a concern. The formulation minimizes carbon deposit and sludge buildup, which are common issues that can impair compressor efficiency over time, leading to costly maintenance and downtime. The presence of robust lubricating properties ensures that the compressor's components operate smoothly, reducing friction and wear.

Moreover, industry standards emphasize the importance of selecting the right lubricant to meet the demands of high-temperature operations typically found in industrial settings. Reported findings suggest that compressors utilizing advanced synthetic fluids exhibit lower energy consumption rates due to reduced frictional losses, which is crucial in optimizing overall system efficiency. By leveraging the benefits of high-performance lubricants, industrial organizations can enhance their operations while safeguarding equipment longevity and reliability.

FAQS

: Synthesis lubricants are advanced lubricants manufactured using sophisticated chemical processes that provide superior thermal stability and lower volatility compared to conventional lubricants. This leads to enhanced performance and longevity for air compressors.

Synthesis lubricants can extend the service life of air compressors by up to 30% due to their ability to resist breakdown under extreme temperatures and prolonged use, significantly reducing wear and tear on the equipment.

The use of synthesis lubricants can decrease energy consumption by approximately 5-15%, translating into notable cost savings for operators by promoting a more efficient operating environment.

Synthesis lubricants can extend maintenance intervals by reducing wear on moving parts and helping to maintain protective properties over extended periods, thereby reducing downtime and operational costs.

Synthesis lubricants form a consistent protective film that minimizes metal-to-metal contact, which is a primary source of wear and tear, leading to smoother operation and improved performance.

Yes, synthesis lubricants exhibit enhanced fluidity in cold temperatures, allowing for quicker lubrication of moving parts during startup, while conventional oils may thicken and cause potential wear.

Synthesis lubricants generally include additives that resist foam formation, keep dirt in suspension, and combat wear more effectively than conventional oils, ensuring smoother and more reliable operation.

By offering extended service life, lower energy consumption, and less frequent maintenance needs, synthesis lubricants contribute to overall reduced operational costs for air compressor users.

Conclusion

Synthesis lubricant for air compressor offers numerous advantages that significantly enhance the performance and longevity of air compression systems. These advanced lubricants improve efficiency by providing superior lubrication compared to conventional oils, reducing friction and energy consumption. Additionally, they play a crucial role in wear reduction, helping to extend the lifespan of the compressor by minimizing component degradation and operational wear.

Moreover, adopting synthesis lubricants can help dispel common misconceptions surrounding industrial lubricant use. By following best practices for their application, users can fully benefit from the enhanced protection and efficiency that synthesis lubricants provide, ultimately leading to more reliable and efficient air compressor operations. As industries seek solutions to optimize performance, the use of synthesis lubricants will continue to demonstrate their value in maintaining air compression systems.

Related Posts

-

Understanding the Versatility of 3 In 1 PTFE Lubricant: How It Enhances Performance Across Industries

-

How to Effectively Use Ptfe Spray Lubricant for Optimal Performance

-

How to Choose the Right Airhorse Compressor Lubricant for Optimal Performance and Longevity

-

Exploring the Future: What Makes Ionic Liquid Compressors a Game-Changer in Industry?

-

Essential Checklist for Choosing the Right Cyclone Dust Collector Supplier

-

Maximizing Efficiency: How Industrial Dust Collectors Reduce Airborne Particles by 95% in Manufacturing Facilities

Blog Tags: