Top 10 Vacuum Pump Oil Types: Which One is Best for Your Needs?

Table of Contents

- Understanding Vacuum Pump Oils: Importance and Functionality

- Common Types of Vacuum Pump Oils: An Overview

- Viscosity and Its Impact on Vacuum Pump Oil Performance

- Synthetic vs. Mineral Oil: Which is Right for Your Vacuum Pump?

- Factors to Consider When Choosing Vacuum Pump Oil

- Maintenance Tips for Extending Vacuum Pump Oil Life

- Popular Brands and Their Offerings in Vacuum Pump Oils

- FAQS

- Conclusion

- Related Posts

When it comes to industrial and lab setups, choosing the right vacuum pump oil really matters — and honestly, it can’t be stressed enough. I came across a recent report from Research and Markets, and it says the global vacuum pump market is projected to hit around $5.9 billion by 2026. A pretty big chunk of that is spent on the specialized oils that help keep these pumps running smoothly and efficiently. These oils aren’t just about lubrication; they also help prevent wear and tear, which is super important, especially in high-stakes industries like pharmaceuticals or making semiconductor chips.

Knowing what kinds of vacuum pump oils are out there is pretty crucial if you want your equipment to last and perform at its best. For example, mineral oils are usually the go-to because they’re cheaper, but synthetic oils often beat them when it comes to handling heat and staying stable at higher temperatures. A study from the National Institute of Standards and Technology even points out that choosing the wrong oil can lead to costly downtime and frequent maintenance — so making the right call is a big deal. In this article, I’ll walk you through the top 10 vacuum pump oils to help you get the info you need to pick the best one for your specific setup and needs.

Understanding Vacuum Pump Oils: Importance and Functionality

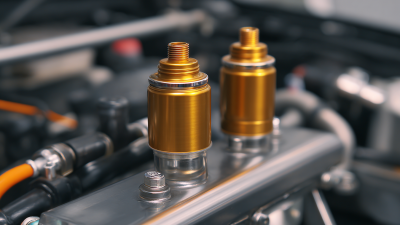

Vacuum pump oils are critical in ensuring the efficient operation and longevity of vacuum pumps. Their primary function is to create a seal within the pump, which enables the removal of air and other gases from enclosed spaces. This sealing action minimizes leakage, maintaining the necessary suction levels for effective performance. Additionally, vacuum pump oils facilitate lubrication, reducing friction between moving parts and thereby preventing wear and tear. Choosing the right type of oil can significantly affect the pump's functionality and overall reliability.

Understanding the different types of vacuum pump oils is essential for selecting the best one for specific applications. Oils can vary based on their viscosity, chemical composition, and temperature tolerance. For instance, mineral oils are commonly used due to their cost-effectiveness and general suitability; however, synthetic oils often provide superior performance in extreme conditions, like high temperatures or aggressive chemical environments. Selecting the correct oil not only optimizes the pump's performance but also extends its operational lifespan, thus benefiting both the equipment and the processes it supports.

Common Types of Vacuum Pump Oils: An Overview

When it comes to selecting vacuum pump oils, it’s essential to understand the common types available to determine which best suits your specific needs. The oil is crucial for the smooth operation and longevity of vacuum pumps, impacting performance and efficiency. There are various categories of vacuum pump oils, including mineral-based oils, synthetic oils, and biologically biodegradable options.

Mineral oils offer high performance for standard applications, while synthetic oils provide better thermal stability and longer service life, making them ideal for more demanding environments.

Biodegradable oils are gaining popularity due to their eco-friendly properties, catering to industries with environmental considerations.

In addition, it is vital to consider the type of vacuum pump in use, as some pumps, like dry pumps, do not require oil at all. Instead, these systems operate without lubrication, reducing maintenance needs and potential contamination risks. For specific applications, such as food processing, oil-free options are increasingly preferred to ensure product purity. Ultimately, evaluating the operating conditions, compatibility with specific pump designs, and environmental impact will guide users in selecting the most appropriate vacuum pump oil for their operations.

Viscosity and Its Impact on Vacuum Pump Oil Performance

Viscosity is a critical factor in determining the performance of vacuum pump oils. It refers to the thickness or resistance to flow of a liquid, which influences how effectively the oil can lubricate and protect the pump's internal components. In vacuum applications, high-viscosity oils provide better protection under extreme temperatures and pressures, ensuring a stable operation. However, they can also lead to increased drag in the system, potentially resulting in higher energy consumption and strain on the pump.

Conversely, low-viscosity oils allow for smoother movement within the pump, enhancing efficiency and reducing wear. These oils are particularly beneficial in applications requiring quick startup or frequent cycling. Choosing the right viscosity is essential for optimizing the vacuum pump's lifespan and performance. Factors such as operating environment and specific application demands must be considered to select an oil that strikes the right balance between lubrication and efficiency.

Synthetic vs. Mineral Oil: Which is Right for Your Vacuum Pump?

When choosing the right oil for your vacuum pump, one critical decision revolves around the choice between synthetic and mineral oils.

Synthetic oils offer enhanced stability and performance under extreme conditions, making them ideal for high-demand applications. They tend to resist oxidation better and provide superior lubrication properties, which can prolong the life of your equipment. On the other hand, mineral oils are more cost-effective and might be perfectly adequate for standard operations, particularly in less demanding environments.

Tips: When selecting oil for your vacuum pump, consider the operating temperature and the specific requirements of your machinery. For applications requiring high reliability and lower maintenance, synthetic oils may justify their higher price. Conversely, if your operations don't expose the equipment to harsh conditions, a high-quality mineral oil could suffice.

Furthermore, it’s essential to conduct regular checks on your lubricant to ensure optimal performance. Developing effective maintenance routines can prevent buildup and extend the life of both your vacuum pump and its lubricating oil, ultimately contributing to enhanced operational efficiency.

Factors to Consider When Choosing Vacuum Pump Oil

When choosing the right vacuum pump oil for your needs, several key factors come into play. First and foremost, the type of vacuum pump you are using is crucial. Different pumps operate in various environments and have distinct characteristics that dictate the kind of oil required. For instance, rotary vane pumps typically necessitate oil that can withstand high temperatures and provide excellent lubrication, while diaphragm pumps may require synthetic oils that minimize contamination.

Another important consideration is the viscosity of the oil. The viscosity affects how well the oil can lubricate the vacuum pump and maintain efficiency. Thicker oils provide better lubrication but may be less effective in low-temperature applications. Additionally, compatibility with the chemicals being handled in the vacuum process is vital; using the wrong oil can lead to chemical reactions that might damage the pump. Finally, evaluating the oil's ability to resist oxidation, its thermal stability, and the frequency of changes needed will ensure optimal performance and longevity of your vacuum pump.

Top 10 Vacuum Pump Oil Types: Which One is Best for Your Needs?

| Oil Type | Viscosity (cSt at 40°C) | Boiling Point (°C) | Applications | Advantages |

|---|---|---|---|---|

| Mineral Oil | 32 | 260 | General vacuum applications | Cost-effective, good lubrication |

| Synthetic Oil | 46 | 300 | High-performance systems | Longer life, high thermal stability |

| PAG Oil | 68 | 290 | Specialized vacuum pumps | Water-soluble, excellent lubrication |

| Vacuum Grease | - | - | High load applications | Very high viscosity, stays in place |

| Food Grade Oil | 32 | 250 | Food processing equipment | Non-toxic, safe for food contact |

| Vacuum Pump Oil E | 68 | 315 | Industrial vacuum applications | Excellent thermal and oxidative stability |

| Hydraulic Oil | 46 | 300 | Transfer in hydraulic systems | Versatile, good for pressure applications |

| Silicone Oil | 10 | 230 | High-temperature applications | Good stability, resistant to oxidation |

| Piston Pump Oil | 32 | 250 | Piston vacuum pumps | Effective in high vacuum levels |

| Refrigerant Oil | 68 | 300 | Refrigeration and cooling systems | Compatible with refrigerants, good lubrication |

Maintenance Tips for Extending Vacuum Pump Oil Life

Proper maintenance of vacuum pump oil is crucial for ensuring the efficiency and longevity of your vacuum pump. One of the primary tips for extending the life of vacuum pump oil is to regularly monitor its condition. Implement a routine schedule for checking the oil's clarity and viscosity; dirty or thickened oil can lead to compromised pump performance. Replace the oil as per the manufacturer’s recommendations and more frequently if the pump operates under harsh conditions or processes that generate contaminants.

Another essential maintenance tip involves managing the operating temperature of the pump. Excessive heat can degrade oil quality, so it’s important to keep the pump within the recommended temperature range. Utilize effective cooling systems if needed, and monitor for any unusual temperature spikes during operation. Additionally, investing in high-quality oil products specifically designed for your vacuum pump can significantly impact oil longevity. Compatibility with the pump's operating conditions ensures better performance and reduces the frequency of oil changes.

Popular Brands and Their Offerings in Vacuum Pump Oils

When selecting vacuum pump oils, it's essential to consider the offerings of popular brands known for their reliability and performance. Notable brands such as Mobil, Bel-Ray, and Total specialize in high-quality vacuum pump oils formulated to enhance the efficiency and longevity of your equipment. According to a report by Research and Markets, the global vacuum pump oil market is projected to grow steadily, driven by increased industrial automation and the rising demand for vacuum technology across various sectors. This trend highlights the importance of choosing the right oil to maintain optimal pump operations.

When evaluating different brands, pay attention to their viscosity ratings and thermal stability. For instance, Mobil’s vacuum pump oils are often praised for their excellent thermal stability, which reduces the risk of oil degradation during extended service. Additionally, Bel-Ray offers a range of synthetic oils that offer superior lubrication under extreme conditions, making them suitable for high-performance applications.

**Tips:** Always refer to your vacuum pump manufacturer's specifications to choose an oil that matches the required viscosity. Regularly monitoring the oil quality and replacing it at recommended intervals can prevent costly repairs and downtime. Furthermore, consider trialing a few types before settling on one to find the best fit for your specific needs.

Top 10 Vacuum Pump Oil Types: Comparison of Their Properties

FAQS

: The primary function of vacuum pump oils is to create a seal within the pump, allowing for the removal of air and gases while minimizing leakage and maintaining necessary suction levels.

Lubrication is essential as it reduces friction between moving parts, preventing wear and tear, and ensuring efficient operation and longevity of the vacuum pump.

Common types of vacuum pump oils include mineral-based oils, synthetic oils, and biodegradable oils, each having different performance characteristics suitable for various applications.

Synthetic oils offer enhanced stability and performance under extreme conditions and better oxidation resistance, while mineral oils are more cost-effective and suitable for standard operations.

Factors to consider include the type of vacuum pump in use, operating conditions, required viscosity, chemical composition, and environmental impact.

Yes, certain types of vacuum pumps, like dry pumps, do not require oil and operate without lubrication, reducing maintenance and contamination risks.

Choosing the appropriate oil can optimize pump performance and reduce wear, ultimately prolonging the equipment's operational lifespan and ensuring reliable performance.

Biodegradable oils are gaining popularity due to their eco-friendly properties, making them suitable for industries with environmental considerations.

Regular checks and effective maintenance routines can prevent lubricant buildup, extend both the pump's and oil's life, and enhance overall operational efficiency.

Synthetic oils should be preferred in applications requiring high reliability and performance under harsh conditions, while mineral oils may be sufficient for standard operations.

Conclusion

When it comes to selecting the right Vacuum Pump Oil Type for your needs, understanding the importance and functionality of these oils is crucial. Several common types of vacuum pump oils are available, each with unique properties impacting performance. Viscosity plays a significant role in how well the oil will perform under various conditions, and choosing between synthetic and mineral oils can greatly affect the efficiency and longevity of your vacuum pump.

In addition to understanding different Vacuum Pump Oil Types, several factors should be considered when making a selection, including operational conditions and specific pump requirements. Regular maintenance can extend the life of your oil, ensuring optimal performance. Companies like Shanghai Jiongcheng Industrial Co., Ltd. offer advanced lubricants designed for various applications, including vacuum pumps. Their commitment to quality through rigorous testing ensures that your equipment can operate efficiently and reliably.

Related Posts

-

Understanding Vacuum Pump Oil: Essential Insights for Optimal Performance and Longevity

-

10 Best Diffusion Pump Oils for Maximum Performance and Longevity

-

Understanding the Essential Role of Dust Collector Spare Parts in Industrial Efficiency

-

Choosing the Right Manufacturer for Best Micro Air Dust Collectors and Key Features to Compare

-

Why Understanding Mineral Oil Ingredients Matters for Your Health

-

What You Need to Know About Lps 1 Lubricant and Its Unique Benefits

Blog Tags: