Good User Reputation for Metal Desk Coating Solutions - ACPL-316 Screw Air Compressors Fluid – Jiongcheng

Short Description:

Good User Reputation for Metal Desk Coating Solutions - ACPL-316 Screw Air Compressors Fluid – Jiongcheng Detail:

Compressor Lubricant

Class III hydrogenated base oil+High performance compound additive

Product Introduction

It is formulated with high-quality synthetic base oil and carefully selected high-performance additives. It has good oxidation stability and high and low temperature stability, with very little carbon deposits and sludge formation, which can extend compressor life and reduce operating costs. The working time is 4000-6000 hours under working conditions, which is suitable for all screw type air compressors.

ACPL-316 Product Performance And Feature

● Good oxidation stability and high temperature stability

● Low carbon residual rate

● Excellent anticorrosion, wear resistant and water separability

● Service life: 4000-6000H, 6000H in standard working condition

● Applicable temperature: 85℃-95℃

● Oil change cycle: 4000H, ≤95℃

Purpose

ACPL 316 is the reliable and economical mineral oil, which is developed as the third hydrogen base oil to cover all basic performance for compressors. It is very economically valued for 3000H compressor running time applications. It is mostly used for most of the China branded compressors and some other global brands such as Atlas Copco etc.

| PROJECT NAME | UNIT | SPECIFICATIONS | MEASURED DATA | TEST METHOD |

| APPEARANCE | - | Colorless to pale yellow | pale yellow | Visual |

| VISCOSITY | 46 | |||

| DENSITY | 25oC,kg/l | 0.865 | ||

| KINEMATIC VISCOSITY @40℃ | mm2/s | 41.4-50.6 | 46.5 | ASTM D445 |

| KINEMATIC VISCOSITY @100℃ | mm2/s | measured data | 7.6 | ASTM D445 |

| VISCOSITY INDEX | 130 | |||

| FLASH POINT | ℃ | > 220 | 253 | ASTM D92 |

| POUR POINT | ℃ | < -21 | -36 | ASTM D97 |

| ANTI FOAMING PROPERTY | ml/ml | < 50/0 | 0/0, 0/0, 0/0 | ASTM D892 |

| TOTAL ACID NUMBER | mgKOH/g | 0.1 | ||

| DEMULSIBILITY (40-37-3)@54℃ | min | < 30 | 10 | ASTM D1401 |

| CORROSION TEST | pass |

The performance of the lubricant will change due to the power loading, unloading pressure, operating temperature, also the original lubricant composition and the residue of the compressor.

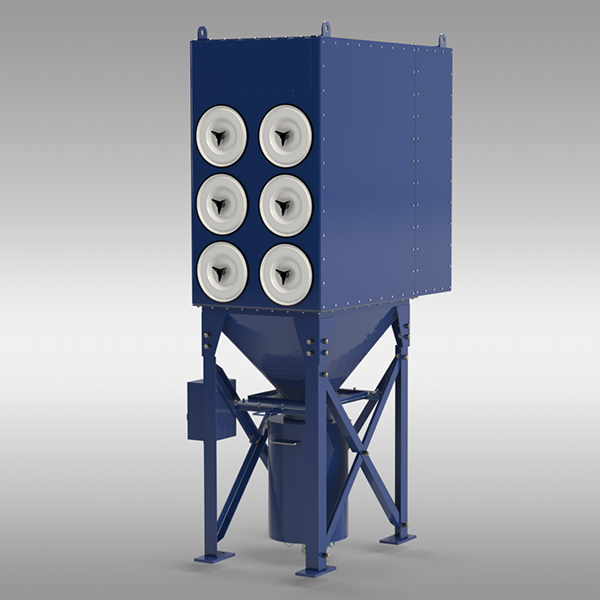

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for Good User Reputation for Metal Desk Coating Solutions - ACPL-316 Screw Air Compressors Fluid – Jiongcheng, The product will supply to all over the world, such as: The Swiss, Libya, Rome, Now we've been sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!