Understanding the Functionality of Baghouse Dust Collector Systems

Table of Contents

- Overview of Baghouse Dust Collector Systems and Their Importance

- Key Components of Baghouse Dust Collector Systems Explained

- How Baghouse Dust Collectors Operate: A Step-by-Step Guide

- Common Applications and Industries Utilizing Baghouse Systems

- Maintenance Tips for Optimal Performance of Baghouse Dust Collectors

- Troubleshooting Common Issues in Baghouse Dust Collector Systems

- Optimizing Cement Factory Operations: The Essential Role of Baghouse Dust Collectors

- FAQS

- Conclusion

- Related Posts

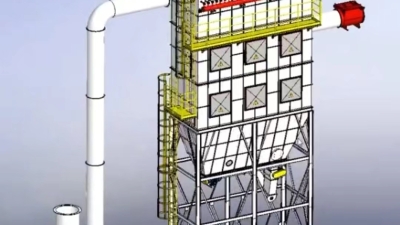

In industrial settings where dust and tiny particles are a big concern, having an effective dust collection system is pretty much a must. It’s not just about keeping things safe and following regulations but also about making sure your machinery runs smoothly. One of the top options out there is the Baghouse Dust Collector. Think of it as a high-tech filter that traps airborne dust while still letting air flow freely.

At Shanghai Jiongcheng Industrial Co., Ltd., we’re always working on new and better ways to deliver top-notch industrial solutions. That’s why understanding how Baghouse Dust Collectors work is so important. Plus, we’re really focused on providing reliable lubrication solutions—like for compressors and vacuum pumps—because keeping these parts well-lubed is key, especially in dusty, high-temp environments.

When our lubricants perform their best under tough conditions, it helps extend the life of the equipment and keeps workplaces cleaner and safer for everyone.

Overview of Baghouse Dust Collector Systems and Their Importance

Baghouse dust collectors are honestly pretty vital when it comes to keeping the air clean and making sure workplaces stay safe in a bunch of different industries. Basically, these systems are built to catch and filter out airborne particles so they don’t just get released into the environment. That’s especially important in fields where dust and pollutants pose real health risks or cause environmental issues. By using fabric filters to trap all those tiny dust particles, baghouses not only help companies stay within legal standards but also keep machinery running smoothly—since less dust means less damage and fewer breakdowns.

Lately, there have been some cool upgrades, like pulse-jet cleaning systems, that make these baghouse systems even more effective. These new cleaning methods kick in periodically to clear out built-up dust, which means the filters stay in good shape longer. That helps the equipment last longer and cuts down on downtime—pretty handy, right? Plus, innovations like dry fog technology show how industries are always looking for smarter ways to handle dust during material handling. As everything keeps evolving, the importance of reliable dust collection systems—like baghouses—remains a big deal for safety and sustainability overall.

Understanding Baghouse Dust Collector Systems

This chart illustrates the effectiveness of baghouse dust collector systems based on different filtration efficiencies. The data represents the percentage of air contaminants captured versus the type of materials processed.

Key Components of Baghouse Dust Collector Systems Explained

Baghouse dust collectors are super important when it comes to keeping the air clean and making sure industries stay within environmental rules. At the core of these systems are a few key parts that work together to trap and get rid of dust and tiny particles from industrial emissions. The main components you’ll find are filter bags, a cleaning system, a fan, and a control unit. According to the EPA, when everything’s working properly, baghouses can cut dust emissions by over 99%, which is way better than many other dust collection methods out there.

Now, these filter bags are made from different materials depending on what kind of dust or temperature the system has to handle — so each setup is tailored to fit specific needs. The cleaning part of the system is pretty crucial for keeping things running smoothly; it usually uses pulse jets or mechanical shaking to loosen and remove the collected dust. A report from the Industrial Ventilation Committee actually mentions that if these systems aren’t maintained well, they can lose up to 20% of their efficiency — so regular upkeep really makes a difference.

The fan's job is to create the airflow needed to pull the dust in, and the control system keeps an eye on everything inside, making sure everything’s running at its best. Understanding these components is key for industries not only to protect workers but also to help out with environmental sustainability — it’s all about doing things right and keeping our air clean.

How Baghouse Dust Collectors Operate: A Step-by-Step Guide

Baghouse dust collectors are really key when it comes to keeping the air clean in industrial settings. They do a pretty great job at trapping those tiny particles that come from emissions. Basically, the process goes something like this: contaminated air comes in and passes through fabric filter bags. As it flows through, most of the larger dust particles get caught in the filters, letting cleaner air go out the other side. This way, the air that leaves the system has way fewer pollutants, helping improve air quality overall.

But here’s the thing—if you want the baghouse to keep working well, regular filter cleaning is a must. One of the most common ways to do this is with reverse pulsed-flow cleaning, where bursts of compressed air hit the filters to shake loose any dust that’s built up. This keeps airflow smooth and also helps the filters last longer.

A little tip: regular maintenance checks can really make a difference. Checking the filters and the pulsed-cleaning system can help catch issues early. Also, keeping an eye on the pressure difference across the filters can tell you when it’s time to clean or replace them. Setting up a routine inspection schedule can save you trouble down the line, keeping everything running smoothly and avoiding unnecessary downtime.

Common Applications and Industries Utilizing Baghouse Systems

Baghouse dust collectors are honestly a game-changer when it comes to keeping the air clean in all sorts of industries. You see them everywhere—manufacturing plants, woodworking shops, mines, and even food processing facilities. In manufacturing, these systems do a great job of trapping tiny particles that come off the production lines, which is super important for meeting environmental rules. When it comes to woodworking, they’re lifesavers for catching sawdust and wood chips, helping keep workers safe and the workspace much cleaner.

If you’re thinking about getting a baghouse system for your place, it’s a good idea to consider what kind of dust you’re dealing with—its type and size really matter because that influences which filter media will work best. Also, don’t forget that regular upkeep—like inspections and changing filters—is crucial. That’s what keeps everything running smoothly and extends the life of the equipment.

And don’t overlook how handy baghouses are in chemical processing plants! Here, they handle some pretty hazardous dust, which is key for protecting workers and keeping emissions under control. When they work well, these systems help companies stick to strict environmental standards and make the workplace safer.

A little tip—set up routine checks to catch leaks or clogs early on. Staying on top of regular inspections means less downtime and better efficiency, which can really save a bunch of money in the long run.

Maintenance Tips for Optimal Performance of Baghouse Dust Collectors

Baghouse dust collectors play a pretty important role when it comes to keeping the air clean and cutting down on dust emissions in all sorts of industrial setups. But honestly, to keep them running smoothly, regular maintenance is the name of the game. Giving them a good clean now and then can really make a big difference in how well they perform. Recently, there’s been some cool new research showing that pulse-jet cleaning techniques—especially the more innovative multi-staged, opposing pulse methods—can boost the efficiency of cartridge dust collectors quite a bit.

Here’s a handy tip: make it a habit to check your filters regularly and swap them out when they start to get clogged. Over time, filters can get pretty gunked up, which slows airflow and drags down overall performance. Using those high-tech pulse-jet cleaning methods, particularly the multi-stage ones, can help refresh your filters, keep them working longer, and cut down on the time you spend on maintenance.

Oh, and don’t forget to keep an eye on the can velocity in your bag filters. It might sound a bit technical, but studies show that tuning this setting just right really helps with cleaning performance. When you tweak the operational parameters to suit your specific system, you’ll notice better airflow and fewer filter replacements needed. Following these simple maintenance tips will help keep your baghouse dust collector running at top shape, protecting both the environment and your overall efficiency. Basically, a little regular TLC goes a long way!

Troubleshooting Common Issues in Baghouse Dust Collector Systems

Baghouse dust collectors are pretty much a must-have when it comes to keeping the air clean in industrial environments. But, let's be honest, they’re not perfect and can run into some common hiccups that mess with their performance. One of the usual suspects is filter bag blinding—basically when dust builds up on the surface of the bags, clogging them up and making it harder for air to flow through. To keep things running smoothly, it’s a good idea to do regular check-ups and cleanings; that way, the bags stay effective. Also, keep an eye on the differential pressure across those bags—if you notice it suddenly drops, that’s a sign they might be blinding or clogged up.

Another thing to watch out for is leaks. These can happen at the seams or connections and let dirty air slip out into the environment. Catching leaks early is all about routine maintenance—checking seals and joints regularly can save you a lot of trouble down the line. Using the right materials during construction helps make the whole system more durable and less prone to leaks too. Basically, taking these simple, proactive steps can do a lot to boost the reliability and efficiency of your baghouse system—leading to a cleaner, safer workspace for everyone.

Optimizing Cement Factory Operations: The Essential Role of Baghouse Dust Collectors

In the cement industry, efficient operation is crucial for maintaining productivity and ensuring compliance with environmental regulations. One of the pivotal components in this optimization is the baghouse dust collector, which plays an essential role in managing airborne particulate emissions. A well-designed baghouse can effectively capture dust particles before they escape into the atmosphere, significantly reducing the environmental impact of cement manufacturing processes. According to industry reports, proper dust control can enhance operational efficiency by up to 10%, while also lowering the risk of health hazards for employees.

For instance, at one of Japan's largest cement factories, a baghouse dust collector capable of handling 20,000 m³/hour has been implemented. This system not only addresses dust control but also integrates crucial safety features such as explosion-proof technology and abort gate control. After running for a year, this installation has demonstrated exceptional performance, proving to be a vital asset in enhancing the cement factory’s operations. The continuous monitoring and management of airborne particulates lead to reduced maintenance costs and prolong the lifespan of equipment, according to data published in the Journal of Cleaner Production.

Additionally, knowing that replacement spare parts are taken care of as part of the service ensures that manufacturers can focus on production rather than maintenance issues. Companies investing in high-capacity baghouse dust collectors are strategically positioning themselves to comply with stringent environmental regulations while achieving operational excellence in the competitive cement industry.

FAQS

: A baghouse dust collector system is an industrial ventilation system designed to maintain air quality and minimize dust emissions by filtering airborne particles using fabric filter bags.

Regular maintenance is essential to ensure optimal performance, enhance efficiency, and minimize downtime caused by clogged filters or system failures.

Filters should be regularly inspected and replaced as needed. Implementing advanced cleaning methods, such as pulse-jet cleaning, can also rejuvenate filter performance and extend their lifespan.

Filter bag blinding occurs when dust particles accumulate on the bag surface, reducing airflow and efficiency. Regular inspection and cleaning cycles can help mitigate this issue.

Monitoring can velocity is critical for optimizing cleaning performance, as adjusting this parameter can enhance airflow and reduce the frequency of filter replacements.

Implementing a routine maintenance schedule to check seals and joints, along with using durable materials for construction, can help prevent leaks and improve system reliability.

Indicators include reduced airflow, significant drops in differential pressure across the filter bags, and visible dust escaping from the system.

Pulse-jet cleaning uses innovative techniques to enhance filter performance, helping to remove accumulated dust and extend the lifespan of the filter bags.

Adjusting operational settings to meet the specific requirements of the dust collection system can improve airflow, cleaning efficiency, and reduce maintenance needs.

Using suitable materials can enhance the durability of the dust collector and prevent leaks, ensuring better performance and a safer work environment.

Conclusion

Baghouse dust collectors are pretty essential when it comes to keeping the air clean and making sure workers aren’t breathing in harmful dust particles. If you've ever wondered how they work, this blog breaks it down step-by-step, highlighting their main parts and how they operate. Lots of different industries rely on these systems to keep dust under control and stick to environmental rules — it’s like a must-have for safety and compliance.

Of course, just having the equipment isn’t enough. Regular maintenance is super important to keep everything running smoothly. In the article, we’ve included some handy tips on how to look after your baghouse systems and avoid common issues. When problems do pop up, quick troubleshooting tips come in handy to get things back on track without a hassle.

Being a company that specializes in lubrication solutions, Shanghai Jiongcheng Industrial Co., Ltd. gets how crucial it is to properly maintain equipment like baghouse dust collectors. It not only keeps things running efficiently but also boosts reliability across various industries — after all, smooth operation is the name of the game.

Related Posts

-

Unlocking Premium Quality: Discover the Best Kuvaldaru Cart Price from China's Leading Manufacturer

-

7 Innovative Tips for Understanding the Multi Cyclone Dust Collector Working Principle

-

Choosing the Right Manufacturer for Best Micro Air Dust Collectors and Key Features to Compare

-

What is the Ultimate Guide to the Best Environmental Protection Solutions

-

Top Strategies for Selecting the Best Reliant Dust Collector A Guide for Global Buyers

-

Understanding the Best Benchtop Dust Collector: Key Features and Industry Insights

Blog Tags: