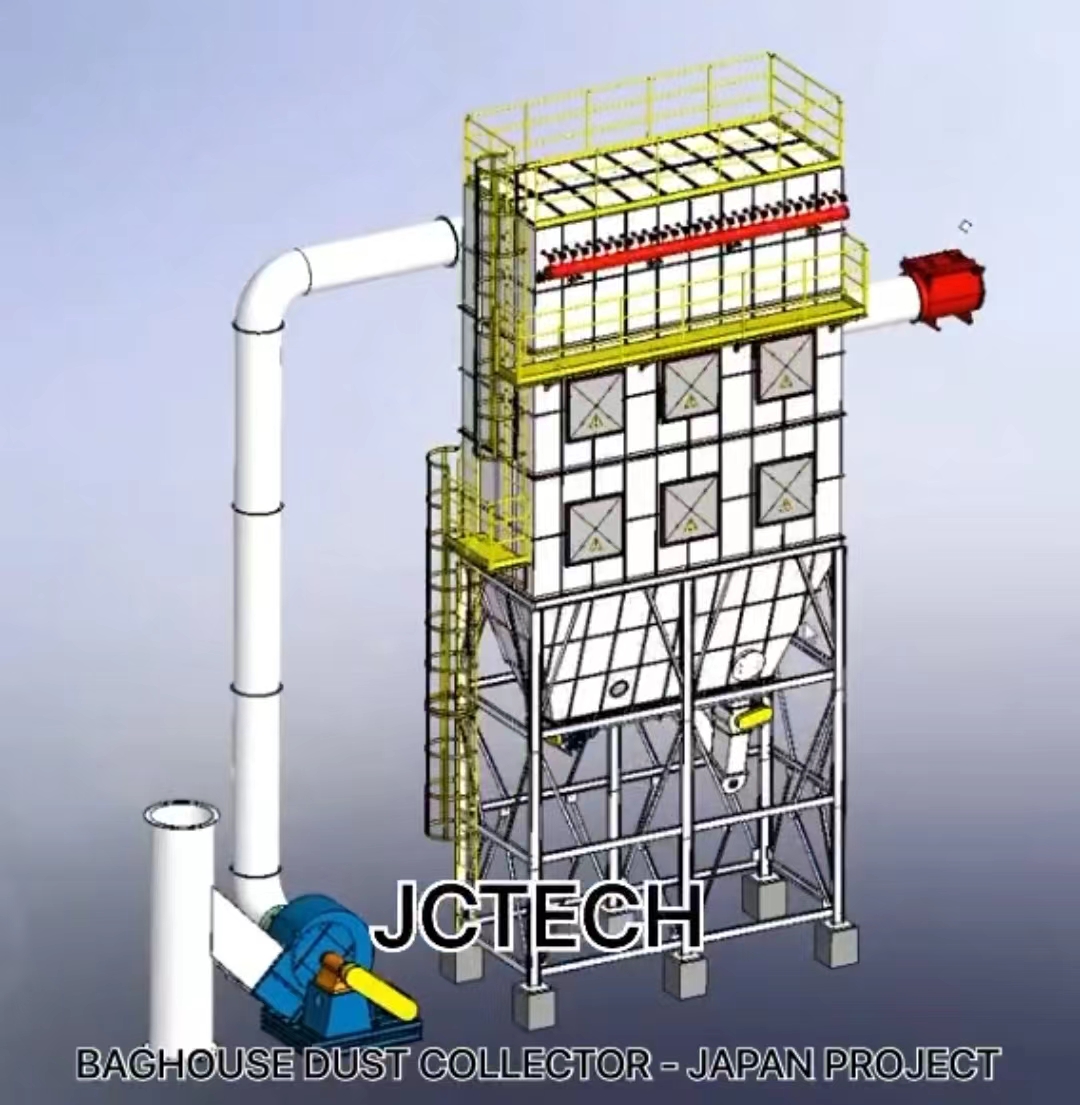

Cement Factory Baghouse Dust Collector

Short Description:

This baghouse dust collector is for the 20000 m3/hour ,one of the Japan biggest cement factory, we provide the solution for dust control and security control like explosion proof and abortgate control. This has been running for one year with wonderful performance, we also take care of the replacement spare parts.

Features

This baghouse dust collector is for the 20000 m3/hour ,one of the Japan biggest cement factory, we provide the solution for dust control and security control like explosion proof and abortgate control. This has been running for one year with wonderful performance, we also take care of the replacement spare parts.

Applicable Industry

A cement plant baghouse is a device designed to capture and remove dust and particulate matter from the air within a cement plant. Since cement production involves multiple processes such as crushing, grinding, and burning, a large amount of dust will be generated. Baghouse dust collectors help maintain clean and safe working conditions by filtering dust particles from the air before they are released into the atmosphere. The following are some of the key features and components of a typical cement plant baghouse: Baghouse: This is the main component that houses multiple filter bags made of fabric or other filter material. These bags act as a barrier, trapping and collecting dust particles while allowing clean air to pass through. Inlet and outlet: Dusty air enters the bag dust collector from the inlet, and clean air is discharged from the outlet after passing through the filter bag. Cleaning system: Over time, dust will accumulate on the surface of the filter bag, reducing filtration efficiency. To remove accumulated dust, baghouses are equipped with cleaning systems that periodically shake or pulse the filter bags to remove dust. This can be done using compressed air or a mechanical vibrating mechanism. Blower: A blower or fan helps create suction that draws dusty air into the baghouse where it can be filtered. It also helps move clean air out of the system. Dust Hopper: When dust is collected in a baghouse, it falls into a dust hopper located at the bottom of the unit. The hopper is designed to easily remove collected dust for disposal or recycling. Monitoring and control systems: Baghouses may be equipped with sensors, instrumentation, and control mechanisms to monitor and regulate airflow, pressure, temperature, and cleaning cycles. This ensures optimal performance and efficient dust removal. Overall, cement plant baghouses play a vital role in maintaining air quality and preventing environmental pollution by effectively capturing and controlling dust emissions during the cement production process.